Discover Top Quality Electric Valves from Leading Manufacturers in China

The global electric valve market is experiencing significant growth, driven by the increasing demand for automation and control systems across various industries. According to a recent report by MarketsandMarkets, the market is projected to reach USD 8.2 billion by 2025, growing at a CAGR of 6.3% from 2020. Electric valves are paramount in applications ranging from water and wastewater management to oil and gas, where precise control is critical. Leading manufacturers in China are at the forefront of this trend, offering innovative and high-quality electric valves that cater to diverse industrial needs. As industries globally shift towards more efficient and automated solutions, understanding the top strategies and products available will be essential for maximizing operational efficiency and ensuring reliability in fluid control systems.

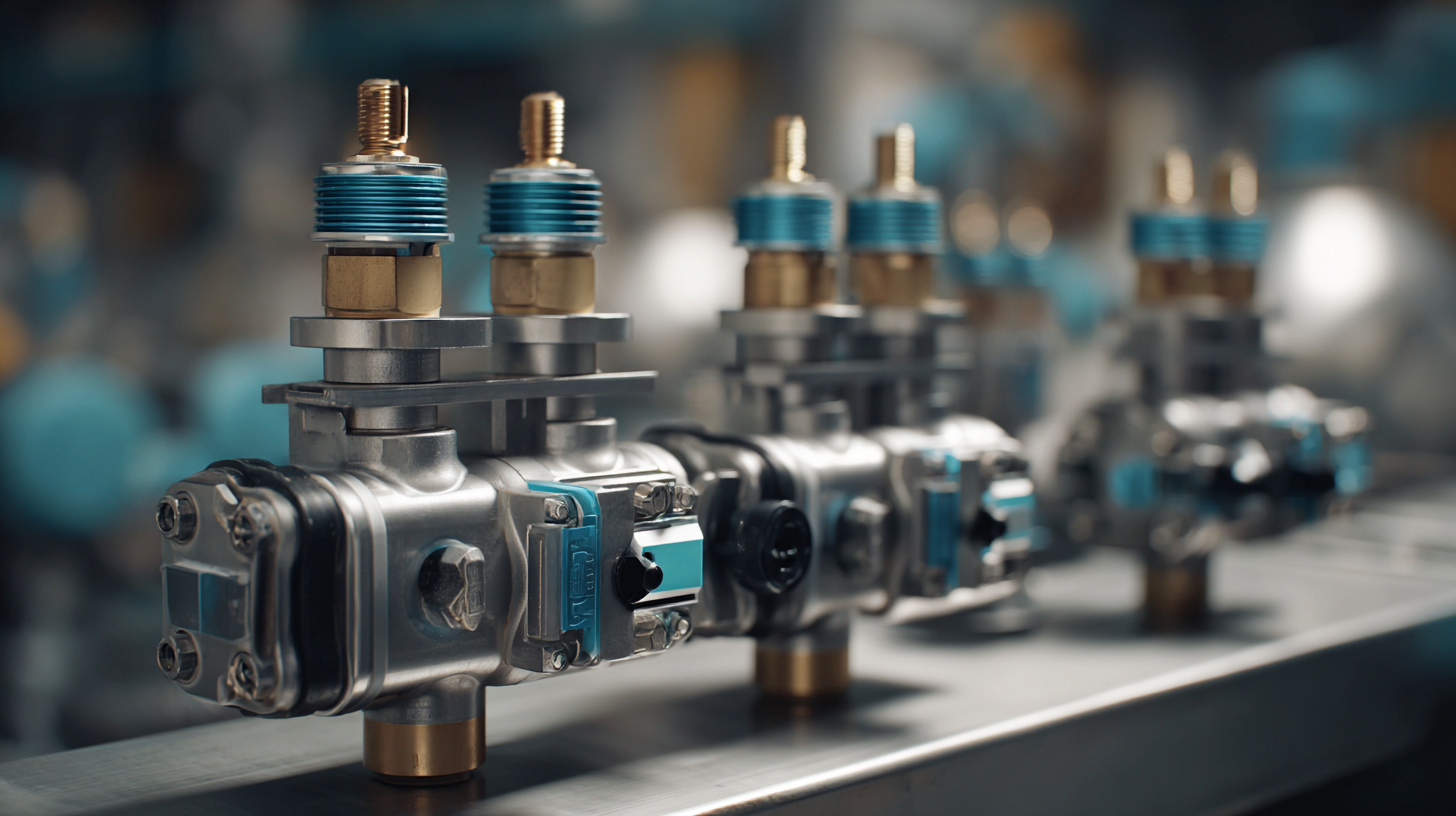

Overview of Electric Valves and Their Applications in Various Industries

Electric valves play a crucial role across various industries, providing vital functionalities in processes that require the control and regulation of fluid flow. These valves are made from a variety of materials, such as silicon, aluminum oxide, and zirconium, which enhance their durability and performance. Different types, inert and active, cater to specific applications, including bearings, grinding, and more. In industrial settings, electric valves are integral to controlling the flow and pressure of gases and liquids, contributing to operational efficiency.

When selecting electric valves, consider the application's specific requirements. For high-temperature or corrosive environments, materials like aluminum oxide may prove advantageous due to their resistance to wear and chemical reactions. Additionally, ensure that the valve’s capabilities align with the system's pressure and flow needs for optimal performance.

**Tips:** Always analyze the installation environment carefully before choosing a valve type. Regular maintenance and inspection can significantly extend the lifespan of electric valves. Lastly, keep an eye on market trends and innovations, as advancements can provide better materials or technologies that improve efficiency and reliability in valve operations.

Discover Top Quality Electric Valves from Leading Manufacturers in China

| Valve Type | Medium | Application Area | Operating Voltage | Features |

|---|---|---|---|---|

| Solenoid Valve | Water, Oil, Air | Automotive, HVAC | 24V, 220V | Compact, Quick Response |

| Motorized Ball Valve | Water, Gas | Plumbing, Industrial | 110V, 230V | Durable, High Flow Rate |

| Electric Butterfly Valve | Liquid, Slurry | Wastewater, Chemical | 24V, 380V | Lightweight, Low Torque |

| Electric Gate Valve | Water, Oil | Oil & Gas, Power Generation | 220V, 400V | Sealing, Customizable |

Key Technical Specifications to Consider When Choosing Electric Valves

When selecting electric valves, understanding key technical specifications is crucial for ensuring optimal performance and durability. One of the primary factors to consider is the valve's duty cycle, which indicates how often the valve can operate within a specific time frame without overheating. A valve designed with a high-duty cycle is essential for applications requiring frequent operation, while those with a low-duty cycle may suffice for less demanding tasks. Additionally, evaluating the valve's actuation speed is important; a fast actuation speed means quicker response times in automated systems, which can enhance overall efficiency.

Another vital specification to review is the voltage and power requirements. Electric valves typically come in various voltage options, including AC and DC, and selecting the right one depends on the existing electrical infrastructure. Compatibility with control systems is also essential; ensure that the electric valve can integrate seamlessly with your control logic to maintain operational efficiency. Furthermore, consider the materials used in the valve construction, as these can significantly impact resistance to corrosion and high pressure, ultimately affecting the valve's lifespan in demanding environments. By carefully assessing these technical specifications, you can make well-informed choices when sourcing high-quality electric valves from leading manufacturers in China.

Leading Manufacturers in China: A Closer Look at Their Product Offerings

China has established itself as a global leader in manufacturing, particularly in the domain of electric valves. Leading manufacturers in China are not only providing high-quality products but also leveraging advanced technologies to meet international standards. According to industry reports, the electric valve market is projected to grow at a CAGR of approximately 6% through 2025, with China accounting for a significant share due to its robust production capabilities and innovative designs.

Notably, Chinese suppliers have embraced e-commerce platforms to showcase their offerings directly to consumers and businesses alike. This shift has allowed manufacturers to reach a broader audience while emphasizing their craftsmanship. Additionally, China's growing emphasis on research and development has resulted in a surge of innovative products, making it imperative for companies to stay updated on the latest advancements in electric valve technology. As the demand for energy-efficient solutions rises, the collaboration between leading manufacturers is poised to further enhance product quality and reliability in the global market.

How to Select the Right Electric Valve for Your Specific Needs

When selecting the right electric valve for your specific needs, the first step is to understand the application requirements. Consider the type of media the valve will control, such as water, gas, or chemicals, as well as the operating temperature and pressure conditions. This analysis ensures that the valve material and size are suitable for both durability and performance in different environments. It’s essential to identify whether you need a normally open or normally closed valve, as this affects the flow direction and overall system operation.

Next, assess the control mechanism that best fits your setup. Electric valves come with various actuation options, including on/off and modulating controls that allow for precise flow regulation. Determine whether a simple electrical signal or a more sophisticated control system integrated with sensors and automation is required for your operations. Additionally, factor in the power supply requirements and compatibility with existing systems to ensure seamless integration. By carefully considering these factors, you can choose an electric valve that optimizes efficiency and meets your operational demands.

Installation and Maintenance Tips for Long-Lasting Electric Valve Performance

Electric valves are essential components in various industrial applications, and their performance greatly depends on proper installation and maintenance. According to a report from the International Society of Automation (ISA), improper installation can reduce the lifespan of electric valves by up to 40%. Therefore, understanding how to properly install and maintain these devices is crucial for optimizing their functionality.

Electric valves are essential components in various industrial applications, and their performance greatly depends on proper installation and maintenance. According to a report from the International Society of Automation (ISA), improper installation can reduce the lifespan of electric valves by up to 40%. Therefore, understanding how to properly install and maintain these devices is crucial for optimizing their functionality.

One key tip for installation is to ensure that the electric valve is aligned correctly with the pipeline system. Misalignment can lead to unnecessary stress on valve components, resulting in premature failure. Additionally, it is advisable to use the proper torque settings when securing the valve to prevent damage to the sealing surfaces. Regular inspections to check for signs of wear or corrosion can also significantly enhance longevity. A study by the Valve Manufacturers Association (VMA) indicates that routine maintenance can increase the lifespan of electric valves by as much as 50%.

For maintenance, a proactive approach is essential. Regularly lubricating moving parts and checking electrical connections can prevent common issues leading to valve malfunction. Using quality replacement parts is equally important; according to industry data, valves using OEM parts show significantly lower failure rates compared to those using generic alternatives. Keeping detailed maintenance records will help track performance over time and inform any necessary operational adjustments. Following these tips ensures that electric valves remain efficient and reliable, minimizing downtime and repair costs in industrial settings.