Top 10 Motorized Valves: Best Options for Efficiency and Control

In recent years, the demand for motorized valves has surged, driven by the increasing need for automation and control in various industrial applications. According to a report by MarketsandMarkets, the global motorized valve market is projected to reach $6.8 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.4% from 2020. This growth is propelled by the expansion of industries such as oil and gas, water and wastewater treatment, and HVAC systems, where precise flow regulation and energy efficiency are paramount.

Motorized valves offer significant advantages over manual counterparts, including enhanced efficiency, reduced labor costs, and improved safety. These valves are pivotal in automating the management of fluids and gases in diverse environments, minimizing the chances of human error while maximizing operational reliability. As industries continue to embrace smart technologies and digital solutions, the role of motorized valves becomes even more critical, integrating with advanced control systems to optimize performance and conserve energy.

This article presents a comprehensive overview of the top 10 motorized valves, focusing on their efficiency, reliability, and functionality in various applications. By exploring the best options available, we aim to aid businesses in making informed decisions that align with their operational goals and sustainability initiatives. Whether for large-scale industrial applications or smaller installations, understanding the range of motorized valves can significantly impact performance outcomes and overall system efficiency.

Understanding Motorized Valves: Definition and Functionality

Motorized valves play a crucial role in various industrial processes, acting as automated devices that facilitate the control of fluid flow. Defined as valves equipped with an electric actuator, these valves are capable of adjusting their position based on external commands from control systems. The functionality of motorized valves is essential in environments where precise flow regulation is necessary, such as in chemical processing, water treatment, and HVAC systems. According to recent industry reports, the global demand for motorized valves is expected to grow at a compound annual growth rate (CAGR) of 5.2% through 2027, underscoring the increased reliance on automation for efficiency.

The operational dynamics of motorized valves involve converting electrical energy into mechanical energy, allowing for rapid and accurate adjustments to flow rates. This adaptability not only enhances operational efficiency but also minimizes energy consumption in processing plants. A technical report from a leading industry analytics firm emphasizes that implementing motorized valve systems can reduce operational costs by up to 20%, supporting sustainability initiatives by optimizing energy use. Furthermore, with advancements in smart technology, these valves can integrate with modern control systems, further improving monitoring capabilities and overall system performance.

Types of Motorized Valves: Exploring Various Designs and Applications

Motorized valves are critical components in various industrial applications, offering enhanced efficiency and control over fluid flow. These valves come in several designs, each tailored for specific operational requirements. The most common types include

globe,

ball,

butterfly,

and

gate valves, each reflecting unique characteristics suited for particular environments.

For instance, globe valves are typically used for throttling flow, providing precise control, while ball valves are favored for their rapid on-off operations and low-pressure drops. According to a report by MarketsandMarkets, the global motorized valve market is projected to grow at a

CAGR of 7.1%

from 2021 to 2026, highlighting the increasing reliance on automation in fluid control systems.

Moreover, the applications of motorized valves span across multiple industries, including

water treatment,

oil and gas, and

HVAC systems.

In water treatment facilities, for example, motorized valves can significantly enhance the efficiency of processes like filtration and disinfection. A study from the American Society of Mechanical Engineers indicates that implementing motorized control can improve operational efficiency by as much as

30%.

In contrast, in the oil and gas sector, these valves play a crucial role in maintaining safety and efficiency in pipeline operations, where precise flow regulation is essential. As industries continue to prioritize automation and energy efficiency, the demand for advanced motorized valve solutions is expected to rise, driving innovation in valve design and functionality.

Key Features to Consider When Choosing Motorized Valves

When selecting motorized valves, several key features should be carefully considered to ensure optimal efficiency and control in your systems. First and foremost, the valve's size and compatibility with the existing piping are crucial. An improperly sized valve can lead to pressure loss and energy inefficiency, so it is essential to match the valve specifications with the system requirements. Additionally, look for the valve's flow characteristics; options such as equal percentage and linear flow can affect system performance and control precision.

Another vital aspect is the actuator type. You can choose from electric, pneumatic, or hydraulic actuators, depending on the application needs and the availability of power sources. Electric actuators, for example, are often favored for their precise control and efficiency in applications that require consistent performance. Furthermore, consider the response time and control range of the actuator to ensure it meets the demands of your system.

**Tips:** Always perform a thorough analysis of your application's pressure and temperature ranges to select a valve that can withstand those conditions. Consider the integration capabilities with existing control systems, as advanced options may offer smart control features for improved monitoring and automation. Lastly, always check for any maintenance requirements associated with the valve and actuator, as regular upkeep can significantly extend their lifespan and reliability.

Top 10 Motorized Valves: Best Options for Efficiency and Control

| Valve Type | Actuator Type | Control Method | Size Range (inches) | Material | Temperature Range (°F) | Flow Capacity (CV) |

|---|---|---|---|---|---|---|

| Ball Valve | Electric | On/Off | 0.5 - 12 | Stainless Steel | -20 to 300 | 2-40 |

| Butterfly Valve | Pneumatic | Modulating | 2 - 24 | Plastic | -10 to 220 | 3-100 |

| Gate Valve | Electric | On/Off | 2 - 30 | Bronze | 0 to 450 | 5-60 |

| Globe Valve | Pneumatic | Modulating | 1 - 18 | Cast Iron | -20 to 400 | 1-20 |

| Check Valve | Electric | Automatic | 1 - 10 | Stainless Steel | -40 to 250 | 0.5-15 |

| Pressure Relief Valve | Pneumatic | Automatic | 1 - 8 | Brass | 0 to 400 | 2-12 |

| Solenoid Valve | Electric | On/Off | 0.25 - 2 | Nylon | -4 to 140 | 0.1-5 |

| Three-Way Valve | Electric | Modulating | 0.5 - 6 | Stainless Steel | 0 to 200 | 1-25 |

| Diaphragm Valve | Pneumatic | Modulating | 1 - 12 | Acrylic | -40 to 150 | 1-20 |

Top 10 Motorized Valves: Detailed Reviews of the Best Options

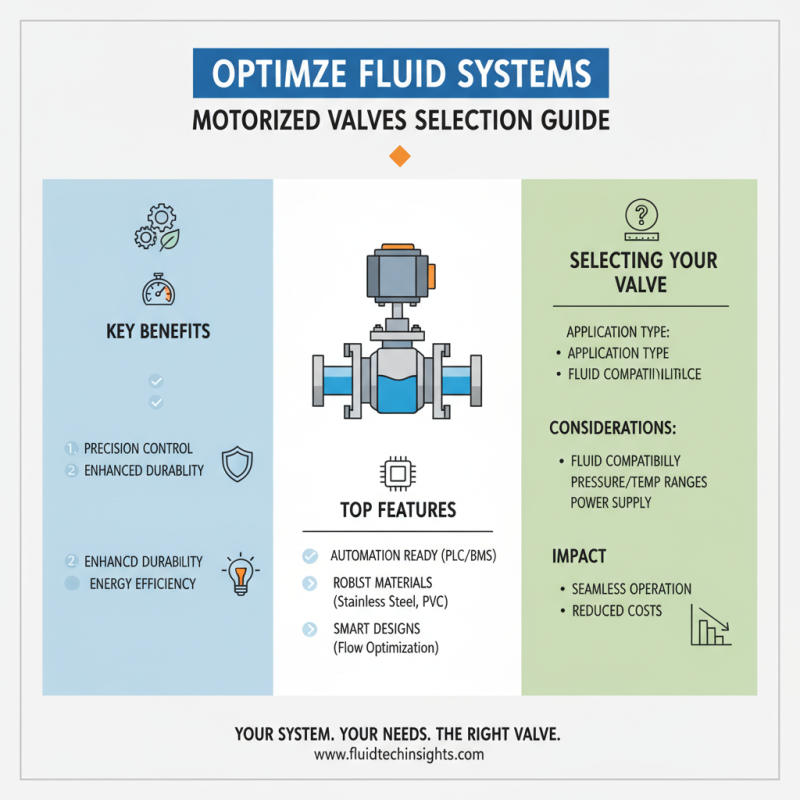

When it comes to optimizing the efficiency and control of fluid systems, selecting the right motorized valve is crucial. The top motorized valves on the market today offer a blend of precision engineering, durability, and advanced features that cater to various industrial and commercial applications. Features such as automation compatibility, robust materials, and energy-saving designs can significantly enhance your system's overall performance. Each valve's unique mechanism can either facilitate seamless operation or contribute to energy conservation, making it essential to evaluate them based on your specific needs.

**Tips:** When looking for a motorized valve, consider the type of control you require—whether on/off, proportional, or modulating control. Additionally, ensure the valve is compatible with the fluids it will handle, as different materials are suited for different applications. Proper sizing and installation can prevent future operational issues, so always reference a professional if you're unsure.

Another key factor in selecting a motorized valve is ease of maintenance. Valves equipped with self-diagnostic features can simplify troubleshooting and help avoid downtime. It's also wise to check for warranties or service agreements that ensure long-term reliability and support. Investing in high-quality motorized valves pays off in the long run, helping you maintain system integrity and reducing operational costs.

Comparison of Efficiency and Control in Leading Motorized Valves

When assessing the efficiency and control of motorized valves, several key performance metrics come into play. According to a recent report by the International Society of Automation, motorized valves can improve operational efficiency by up to 30% compared to manual valves. This enhancement comes from their precise control capabilities, which enable responsive adjustments that align with real-time system demands. The ability to automate flow control not only reduces the risk of human error but also optimizes energy consumption, leading to significant cost savings over time.

Moreover, the evaluation of control precision among leading motorized valves underscores the advancements in technology. Data from the Valve Manufacturers Association indicates that modern motorized valves offer a control accuracy of 1% or better in flow regulation. This level of precision is vital in processes where maintaining specific flow rates is crucial, such as in chemical processing or HVAC systems. As industries increasingly focus on sustainability and operational excellence, the integration of high-performance motorized valves is becoming an essential strategy for enhancing overall system effectiveness and reliability.

Top 10 Motorized Valves: Efficiency and Control Comparison

This chart displays the comparison of efficiency and control precision for the top 10 motorized valves. The dataset highlights how each valve performs in terms of efficiency and control, represented as percentages.

Related Posts

-

Top Strategies for Maximizing Efficiency with Pneumatic Control Valves

-

Global Excellence in Control Valve Manufacturing China Leads the Way

-

How to Choose the Best Motorized Valve for Your Industrial Needs

-

Elevating Global Standards through Best Control Valve Solutions Made in China

-

Discover Top Quality Electric Valves from Leading Manufacturers in China

-

Embracing Innovation in the Future of Best Motorized Valve Technology