Top 10 Pneumatic Valve Types for Optimal Performance in Industrial Applications

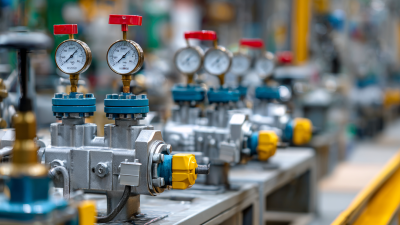

In the world of industrial automation, pneumatic valves play a crucial role in the efficient management of fluid control and pressure regulation. As industries strive for optimal performance and reliability in their processes, understanding the various types of pneumatic valves becomes essential. These components serve as the brain behind many pneumatic systems, seamlessly directing the flow of gases or air within machinery. By selecting the appropriate valve type, companies can enhance their operational efficiency, reduce downtime, and ultimately achieve higher productivity.

This article delves into the top 10 pneumatic valve types that are widely recognized for their effectiveness in various industrial applications. From simple on-off valves to more complex directional control valves, each type has its unique features and benefits that cater to specific needs. The right pneumatic valve can significantly impact system responsiveness and safety, making the choice a critical factor for engineers and decision-makers. As we explore these valve types, we will highlight their applications, advantages, and considerations for implementation, providing a comprehensive guide to optimizing performance in your industrial processes.

Overview of Pneumatic Valves in Industrial Settings

Pneumatic valves play a crucial role in automating industrial processes, offering precise control over fluid movement. In various industrial settings, the demand for effective pneumatic systems has significantly increased, with a report by ResearchAndMarkets indicating that the global pneumatic valve market is expected to reach $4.65 billion by 2026, growing at a CAGR of 4.5%. This growth is driven by the need for efficiency and reliability in sectors such as manufacturing, oil and gas, and pharmaceuticals, where pneumatic valves can enhance operational performance and minimize downtime.

Different types of pneumatic valves, including directional control valves, pressure relief valves, and flow control valves, are integral to ensuring that systems function optimally. Directional control valves, for instance, manage the path of compressed air within pneumatic circuits, facilitating smooth transitions between different operational modes. According to a recent study by IndustryARC, more than 30% of all pneumatic applications utilize directional control valves for their performance reliability. Similarly, pressure relief valves protect systems from overpressure situations, a critical aspect in maintaining safety and compliance in industrial operations. Selecting the appropriate pneumatic valve type not only impacts efficiency but also influences the overall productivity of industrial applications.

Types of Pneumatic Valves: A Comprehensive Breakdown

Pneumatic valves play a crucial role in controlling the flow of compressed air in various industrial applications. Their design and functionality significantly influence system efficiency and operational safety. There are several types of pneumatic valves, each serving specific purposes and offering distinct advantages. Among the most prevalent types are directional control valves, which direct airflow among different pathways, enabling precise control over machinery and processes. These valves can be further categorized into 2/2, 3/2, and 5/2 configurations, depending on the number of ports and positions they offer.

Another important category is pressure control valves, which ensure that the air pressure within the system remains within predetermined limits. These valves include pressure relief and pressure reducing types, vital for maintaining safety and functionality in high-pressure applications. Flow control valves also play a critical role by regulating the speed of actuators, allowing for smooth and controlled operations in pneumatic systems. Overall, understanding the various types of pneumatic valves and their respective functionalities helps in selecting the appropriate components that optimize performance and increase the reliability of industrial systems.

Key Performance Factors for Pneumatic Valves

When selecting pneumatic valves for industrial applications, understanding key performance factors is essential. The durability and reliability of pneumatic valves are pivotal, particularly in environments with high cycles and demanding conditions. Research indicates that valves designed with robust materials and superior sealing technology can withstand significant wear and maintain efficiency over prolonged periods. According to a recent industry report, high-performance valves can improve system efficiency by up to 30%, reducing downtime and maintenance costs.

Another critical factor to consider is response time. A quick-acting valve allows for faster system responsiveness, which can significantly enhance overall production rates. Industries that rely on automation benefit from valves with low hysteresis and minimal actuation delay, as these attributes facilitate precise control of pneumatic systems. Studies show that optimizing response times in pneumatic systems can lead to a 25% increase in throughput, underscoring the importance of valve choice in operational efficiency.

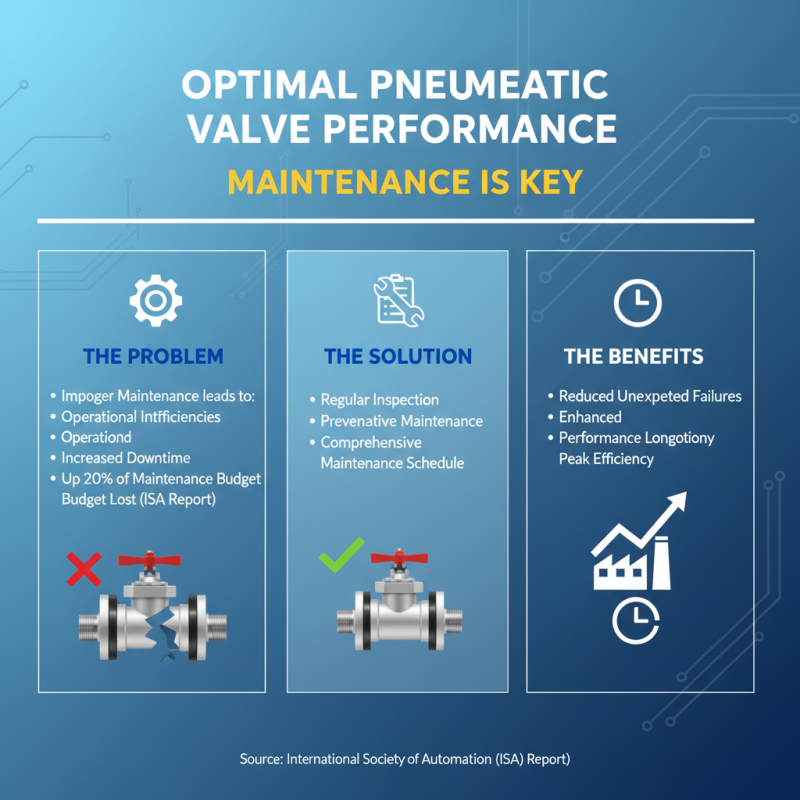

**Tip:** Regular maintenance can significantly extend the lifespan of pneumatic valves. Implementing a preventative maintenance schedule that includes inspections and the timely replacement of wear parts can ensure sustained performance and minimize unexpected failures.

**Tip:** When assessing valve options, consider not only the specifications but also the operating environment. Factors such as temperature fluctuations, exposure to corrosive substances, and pressure variations can all influence valve performance, highlighting the need for tailored solutions to meet specific application demands.

Top 10 Pneumatic Valve Types for Optimal Performance in Industrial Applications - Key Performance Factors for Pneumatic Valves

| Valve Type | Operating Principle | Actuation Method | Key Performance Factor | Common Applications |

|---|---|---|---|---|

| Ball Valve | Rotary motion | Electric, Pneumatic | Low pressure drop | Chemical processing |

| Butterfly Valve | Rotary motion | Pneumatic, Hydraulic | Compact design | HVAC systems |

| Gate Valve | Linear motion | Manual, Electric | Minimal leakage | Water supply |

| Globe Valve | Linear motion | Manual, Pneumatic | Good throttling | Flow regulation |

| Check Valve | Backflow prevention | N/A | Automatic operation | Pump systems |

| Solenoid Valve | Electromagnetic | Electric | Fast response | Automation systems |

| Pneumatic Actuator Valve | Linear or rotary motion | Pneumatic | High speed | Manufacturing |

| Diaphragm Valve | Flexible membrane | Manual, Electric | Excellent sealing | Food processing |

| Safety Valve | Pressure relief | Spring-loaded | Safety compliance | Steam systems |

| Pressure Relief Valve | Pressure control | Spring-loaded | Consistent operation | Petrochemical |

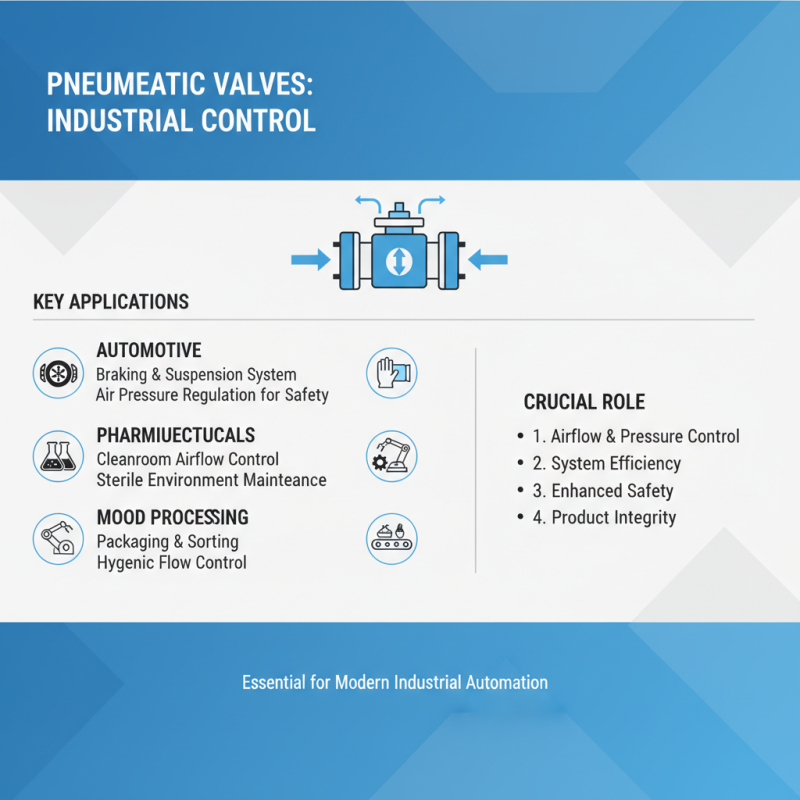

Applications of Pneumatic Valves in Various Industries

Pneumatic valves play a crucial role in various industrial applications, ensuring efficient control of airflow and pressure in systems ranging from manufacturing to food processing. Their functionality extends across different sectors, including automotive, pharmaceuticals, and HVAC systems. In the automotive industry, pneumatic valves are vital for controlling air pressure in components such as brakes and suspension systems, providing enhanced safety and performance. In pharmaceuticals, they help maintain sterile environments by regulating air flows in cleanrooms, thus ensuring product integrity.

When integrating pneumatic valves into industrial processes, it's essential to consider specific operational requirements. Choosing the right type of valve, such as diaphragm or solenoid valves, can significantly impact efficiency and responsiveness.

Tips: Always evaluate the compatibility of the valve materials with the fluids or gases being controlled to avoid corrosion or leaks. Regular maintenance checks can also prolong the life of pneumatic valves and ensure optimal performance, minimizing downtime and maintenance costs. By investing time in proper selection and upkeep, industries can achieve significant operational improvements.

Maintenance Best Practices for Optimal Valve Performance

Proper maintenance is crucial for ensuring optimal performance of pneumatic valves in industrial applications. According to a report by the International Society of Automation (ISA), improper maintenance can lead to operational inefficiencies and increased downtime, costing industries up to 20% of their overall maintenance budget. Regular inspection and preventive maintenance routines significantly reduce the risk of unexpected failures. Establishing a comprehensive maintenance schedule tailored to valve types and operational conditions can enhance performance longevity, ensuring that valves operate at peak efficiency.

Furthermore, lubrication is key for the proper functioning of pneumatic valves. The Pneumatic Systems Association reports that inadequate lubrication can result in increased wear and tear, leading to premature valve failure. Utilizing the right lubrication protocol not only minimizes friction but also prevents dirt and contaminants from entering the system. Industry standards suggest that regular cleaning of valve components should be performed to maintain optimal performance, as even minor build-ups can impede functionality. By implementing these best practices, industries can ensure their pneumatic valves operate reliably, ultimately enhancing overall system efficiency and productivity.

Related Posts

-

How to Select the Best Pneumatic Valve for Your Industrial Applications

-

Top Strategies for Enhancing Efficiency with Pneumatic Valves in Industrial Applications

-

How to Choose the Right Pneumatic Control Valve for Your Industrial Needs

-

Unlocking Efficiency: Technical Specifications of the Best 3 Way Ball Valve and How to Optimize Its Use

-

Understanding the Mechanism Behind Ball Check Valves

-

Top 10 Motorized Valves: Best Options for Efficiency and Control