Exploring the Impact of Motorized Valve Technology on Energy Efficiency in Industrial Applications

The industrial sector is increasingly turning its attention to energy efficiency as a means to reduce operational costs and environmental impact. One innovative technology making significant strides in this area is the motorized valve. According to a report by the International Energy Agency (IEA), motorized valves can optimize fluid flow control, leading to energy savings of up to 30% in various applications, including HVAC systems and manufacturing processes.

These valves are equipped with actuators that enable precise control over fluid dynamics, effectively maintaining optimal operating conditions and minimizing energy loss. This transformative impact of motorized valve technology not only enhances overall system performance but also fosters a more sustainable industrial landscape. By exploring the adoption of motorized valves, we can further understand their vital role in advancing energy efficiency in industrial applications, ultimately contributing to long-term economic and ecological benefits.

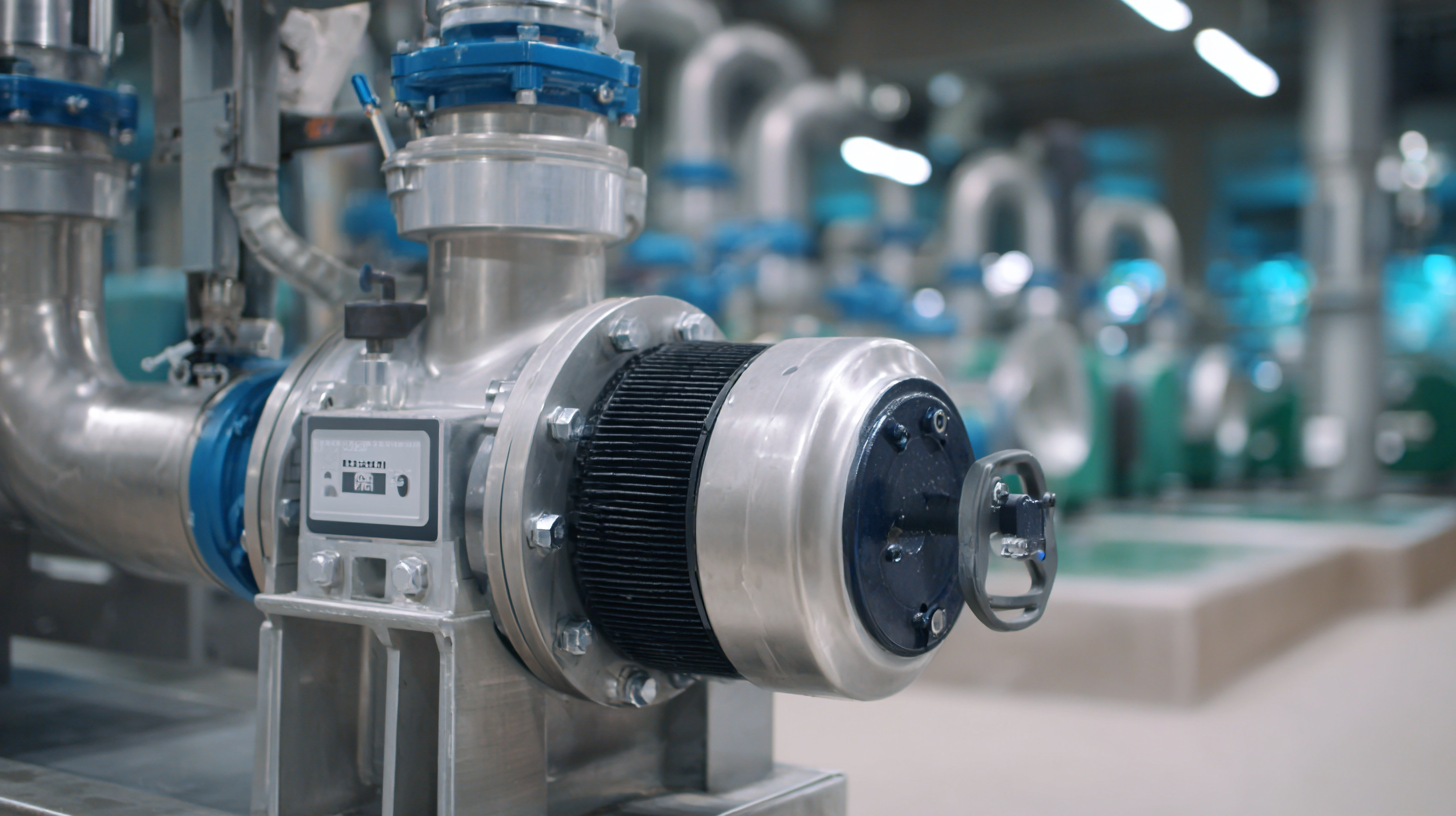

Understanding Motorized Valve Technology and Its Functions

Motorized valve technology plays a crucial role in enhancing the efficiency of various industrial applications. At its core, a motorized valve is an automated device that controls the flow of fluids within a system through mechanical actuation. These valves are often integrated with control systems to respond dynamically to changes in pressure, temperature, and fluid characteristics, ensuring optimal performance. By minimizing human intervention, motorized valves not only streamline operations but also significantly reduce the risk of human error, leading to improved reliability in process management.

The functions of motorized valves extend beyond mere flow control; they can perform tasks such as throttling, diverting, and isolating flow paths. This versatility makes them essential in diverse industries, including water treatment, oil and gas, and HVAC systems. Their ability to provide precise control enables better regulation of energy use, contributing to enhanced energy efficiency. Furthermore, many modern motorized valves are equipped with advanced features such as feedback sensors and communication capabilities, allowing for real-time monitoring and automated adjustments. This integration of technology not only optimizes performance but also supports predictive maintenance, further enhancing the overall energy efficiency of industrial systems.

Key Benefits of Motorized Valves in Enhancing Energy Efficiency

Motorized valve technology has revolutionized the way industries manage fluid control systems, significantly enhancing energy efficiency across various applications. One of the key benefits of motorized valves is their ability to provide precise control over fluid flow, which minimizes energy losses. According to a study by the U.S. Department of Energy, optimizing valve operations can lead to energy savings of up to 30% in HVAC systems alone. This level of efficiency not only reduces operational costs but also contributes to a lower carbon footprint for industrial plants.

Furthermore, motorized valves promote better system responsiveness and reliability. Advanced features, such as automated control and real-time monitoring, enable facilities to adjust their operations to changing demands instantaneously. A report released by the International Energy Agency highlights that integrating smart motorized valves into existing systems can enhance performance by nearly 20%, aligning with the industry's push for sustainable practices.

**Tips:** To maximize the benefits of motorized valve technology, ensure proper installation and regular maintenance checks. Additionally, consider integrating these valves with building management systems to optimize performance further. Adopting smart technologies can ultimately lead to substantial long-term savings and improved operational efficiency.

Impact of Motorized Valve Technology on Energy Efficiency

This bar chart illustrates the impact of motorized valve technology on energy efficiency in industrial applications. The data shows an increase in energy efficiency from 65% to 85% following the implementation of motorized valves, highlighting their key benefits in enhancing energy efficiency.

Case Studies: Successful Implementation in Industrial Settings

In recent years, motorized valve technology has gained significant traction in various industrial sectors, demonstrating impressive enhancements in energy efficiency. Case studies from leading industries showcase the transformative effects of implementing these advanced systems. For example, a chemical manufacturing facility reported a 30% reduction in energy costs following the installation of motorized valves that automatically adjust flow rates based on real-time data. This level of adaptability not only aids in optimizing energy use but also enhances the overall process efficiency.

For those considering a similar upgrade, it’s essential to assess the specific needs of your operation. **Tip:** Conduct a thorough energy audit to identify areas where motorized valves can provide the most impact. Moreover, consider collaborating with experienced vendors who can tailor a motorized valve solution to your unique requirements. In another case, a food processing plant slashed operational costs significantly by retrofitting existing systems with smart motorized valves, which improved product consistency and reduced waste.

**Tip:** Regular maintenance checks are crucial to ensure that motorized valves operate at peak performance. Implementing a scheduled service plan can help detect potential issues early, preventing costly downtimes and ensuring your energy efficiency measures remain effective over time.

Exploring the Impact of Motorized Valve Technology on Energy Efficiency in Industrial Applications

| Application Area | Energy Savings (%) | Implementation Year | Payback Period (Months) | Operational Efficiency Improvement (%) |

|---|---|---|---|---|

| Chemical Processing | 18 | 2021 | 10 | 15 |

| Water Treatment | 25 | 2020 | 8 | 20 |

| HVAC Systems | 30 | 2022 | 5 | 25 |

| Oil & Gas | 15 | 2019 | 12 | 18 |

| Pharmaceuticals | 22 | 2021 | 9 | 30 |

Best Practices for Integrating Motorized Valves in Existing Systems

The integration of motorized valve technology in industrial systems is increasingly recognized as a pivotal factor in enhancing energy efficiency. Recent industry reports highlight that electric actuated valves, such as electric butterfly valves, have become essential components due to their precision and reliability in flow regulation. Specifically, the electric butterfly valve market is experiencing accelerated growth, driven by advancements in actuator technology and rising standards for energy consumption in manufacturing processes. As industries strive to comply with stringent energy policies, the adoption of motorized valves can contribute significantly to reducing operational costs while maximizing performance.

To effectively integrate motorized valves into existing systems, best practices recommend a thorough assessment of current workflows and valve performance metrics. Replacing outdated valve systems with electric alternatives can lead to substantial energy savings—data suggests that modern actuators can offer up to 30% improved efficiency over traditional mechanisms. Furthermore, leveraging smart control systems in conjunction with motorized valves allows for real-time monitoring and optimization of flow rates, ensuring that systems operate within their most efficient parameters. Industries adopting these technologies not only enhance their energy efficiency but also position themselves favorably within the evolving landscape of regulatory standards and consumer demands for greater operational safety and comfort.

Future Trends: Innovations in Motorized Valve Technology for Industry

Innovations in motorized valve technology are paving the way for enhanced energy efficiency in industrial applications. As industries strive to reduce their carbon footprints and optimize energy consumption, advancements such as intelligent control systems and improved actuator designs are becoming vital. These innovations allow for more precise flow control, reducing energy waste and ensuring that processes operate within optimal parameters. With the integration of smart technologies, such as AI and IoT, industries can monitor and adjust valve settings in real-time, further enhancing overall efficiency.

Looking to the future, trends in motorized valve technology are set to transform manufacturing and process industries. Developments in electrification and automation, driven by the demands of Industry 4.0, will lead to the creation of more sophisticated valves that can adapt to changing operational conditions without human intervention. Additionally, the rise of 5G technology will enable faster communication between devices, enhancing coordination and efficiency in industrial processes. As these trends continue to evolve, the role of motorized valves in driving energy efficiency will only grow in significance, supporting sustainable industrial practices and innovation.

Related Posts

-

Discover Top Quality Electric Valves from Leading Manufacturers in China

-

Embracing Innovation in the Future of Best Motorized Valve Technology

-

Innovative Technologies Shaping the Future of Best Pneumatic Ball Valve Solutions and Strategies for Global Procurement

-

Top Strategies for Maximizing Efficiency with Pneumatic Control Valves

-

Mastering the Basics of 3 Way Ball Valve Installation and Maintenance Guide

-

Unlocking Efficiency: Technical Specifications of the Best 3 Way Ball Valve and How to Optimize Its Use