Embracing Innovation in the Future of Best Motorized Valve Technology

As industries evolve towards a more automated and efficient future, the role of motorized valves has become increasingly significant. According to a recent report by MarketsandMarkets, the global motorized valve market is projected to reach USD 3.36 billion by 2025, growing at a CAGR of 5.8% from 2020. This upward trend reflects a larger shift towards advanced control technologies in sectors such as oil and gas, water and wastewater management, and HVAC systems. In this dynamic landscape, embracing innovation in motorized valve technology is crucial for organizations seeking to enhance operational efficiency, reduce costs, and ensure sustainability.

This blog will explore the key technological trends shaping the motorized valve industry by 2025 and provide insights on how to effectively integrate these advancements into existing systems for optimal performance.

The Evolution of Motorized Valve Technology: A Look Ahead

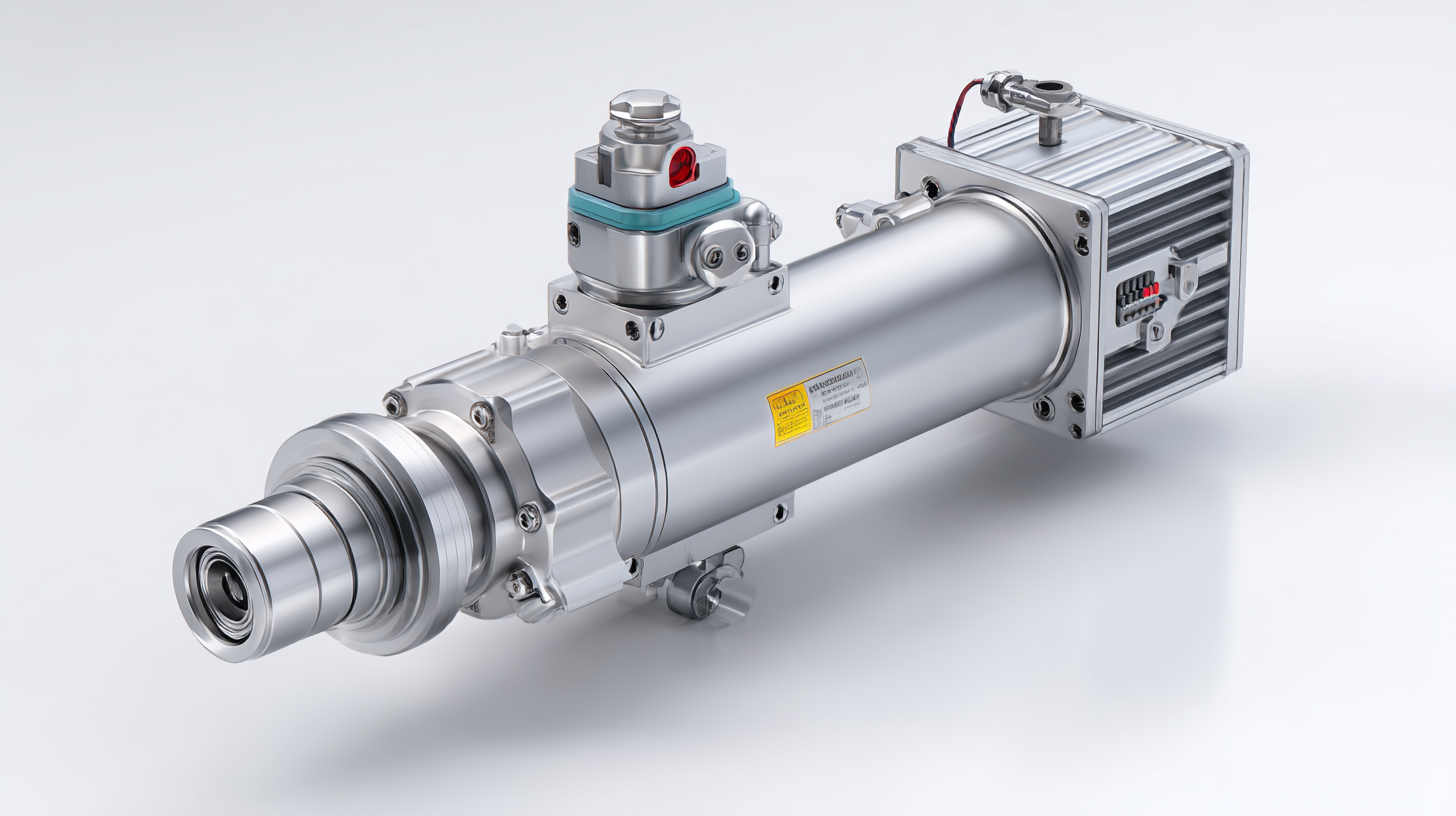

The evolution of motorized valve technology has been a remarkable journey marked by innovation and adaptability. As industries seek more efficient control systems, motorized valves have evolved from simple mechanisms to sophisticated devices equipped with advanced sensors and smart capabilities. This transformation not only enhances operational efficiency but also supports the growing demand for automated solutions in various sectors, including manufacturing, water management, and HVAC systems.

Looking ahead, the future of motorized valve technology is poised for even more dramatic changes. With the integration of IoT (Internet of Things), valves will not only respond to immediate control signals but also communicate data for predictive maintenance and performance monitoring. This shift towards smart connectivity enables industries to optimize their processes, reduce downtime, and ultimately save costs. As we embrace these innovations, the role of motorized valves will expand, paving the way for smarter, more efficient systems that align with the demands of a rapidly changing technological landscape.

Embracing Innovation in Motorized Valve Technology

This chart illustrates the projected market growth percentages for motorized valve technology innovations over the next five years, highlighting sectors like oil & gas, water management, and HVAC systems.

Integrating Digital Solutions for Enhanced Valve Performance

As industries evolve, the integration of digital solutions into motorized valve technology is becoming a game-changer. Enhanced valve performance relies heavily on data-driven insights and real-time monitoring. By embedding sensors and IoT capabilities into motorized valves, operators can gather critical data on valve performance, enabling predictive maintenance and reducing downtime. This innovative approach not only ensures operational efficiency but also promotes a proactive maintenance culture rather than a reactive one.

Furthermore, the adoption of advanced software solutions facilitates seamless control and automation of valve operations. With digital dashboards, engineers can remotely monitor and adjust valves, improving response times during unexpected scenarios. This connectivity opens avenues for sophisticated algorithms that can optimize flow control and reduce energy consumption. By embracing these digital solutions, businesses are not only maximizing performance but also contributing to sustainability goals by minimizing waste and resource usage in their processes. Thus, the future of motorized valves lies in the seamless integration of technology that fosters smarter, more efficient operations.

Key Innovations Driving the Future of Best Motorized Valves

The evolution of motorized valve technology is being shaped by several key innovations that promise to enhance efficiency and reliability in various industries. One significant advancement is the integration of smart controls, which allow for real-time monitoring and automation of valve operations. These smart systems utilize IoT (Internet of Things) connectivity to provide data analytics, enabling operators to make informed decisions and optimize performance. This not only increases operational efficiency but also contributes to proactive maintenance, ultimately reducing downtime.

Another notable innovation is the development of energy-efficient designs. Modern motorized valves are being engineered to consume less power while maintaining their performance levels, making them more environmentally friendly and cost-effective. Advanced materials and manufacturing techniques are also playing a crucial role, resulting in valves that are not only lighter and more durable but also resistant to corrosion and wear. As industries continue to prioritize sustainability and cost savings, these innovations are vital for the future of motorized valves, paving the way for smarter and greener operational practices.

Sustainability and Efficiency: The New Standards in Valve Design

As industries pivot towards sustainability, the focus on efficiency within valve design has reached new heights. Recent studies indicate that the global market for motorized valves is projected to grow significantly, with a compound annual growth rate (CAGR) of 6.6% from 2022 to 2028. This surge is largely driven by the increasing demand for energy-efficient systems and innovative technologies that contribute to reduced operational costs and environmental impacts.

Manufacturers are adopting advanced materials and smart technologies to enhance the performance of motorized valves. Reports suggest that the integration of IoT into valve systems has led to a 20% improvement in energy efficiency, presenting a pivotal shift in how these components function within automated processes. Moreover, sustainable design practices are now being prioritized, with many companies committing to using recyclable materials and implementing waste reduction strategies in their production processes.

As these trends continue to evolve, we can anticipate a new era of valve technology characterized by greater reliability and a commitment to environmental responsibility.

Real-World Applications of Next-Gen Motorized Valve Solutions

In the evolving landscape of industrial automation, next-gen motorized valve solutions are revolutionizing processes across various sectors. According to a recent report by MarketsandMarkets, the global motorized valves market is expected to grow from USD 3.2 billion in 2020 to USD 4.5 billion by 2025, reflecting a compound annual growth rate (CAGR) of 7.2%. This growth is primarily driven by the increasing demand for efficient fluid control systems in industries such as oil and gas, water treatment, and manufacturing.

Real-world applications of these advanced valves showcase their versatility and benefits. For instance, in the oil & gas industry, motorized valves can significantly enhance safety and operational efficiency, enabling rapid response to changing conditions. Furthermore, in water treatment plants, these valves help maintain optimal water quality by providing accurate flow control, which is crucial for meeting regulatory standards. As companies embrace digital transformation, integrating smart technology into motorized valves will facilitate remote monitoring and predictive maintenance, creating a more efficient system overall.

Tip: When selecting motorized valves for your operations, consider factors such as compatibility with existing systems, required flow rates, and the specific conditions of your application. Additionally, ensure that your chosen valves are supported by robust data analytics capabilities to maximize operational efficiency. By doing so, you can achieve significant improvements in both performance and safety.

Embracing Innovation in the Future of Best Motorized Valve Technology - Real-World Applications of Next-Gen Motorized Valve Solutions

| Application Sector | Valve Type | Control Mode | Key Benefits | Operational Range (°C) |

|---|---|---|---|---|

| Water Treatment | Electric Actuated Valve | On/Off | Improved efficiency and maintenance | 0 to 60 |

| Oil & Gas | Pneumatic Valve | Proportional | Increased safety and reduced downtime | -40 to 85 |

| Chemical Processing | Electromotive Valve | Smart Control | Enhanced precision and tracking | -10 to 100 |

| HVAC Systems | Modulating Valve | Automatic | Energy savings and comfort control | 5 to 70 |