How to Choose the Right Pneumatic Control Valve for Your Industrial Needs

In the realm of industrial automation, the selection of a suitable pneumatic control valve is crucial for optimizing processes and ensuring operational efficiency. According to a recent market analysis by Research and Markets, the global pneumatic control valve market is projected to reach $4.7 billion by 2025, growing at a CAGR of 5.2% from 2020. This growth underscores the increasing reliance on pneumatic systems across various sectors, including manufacturing, oil and gas, and pharmaceuticals, where precise control of pressure and flow is vital.

Selecting the right pneumatic control valve can significantly impact the overall performance and reliability of industrial systems. Key factors such as valve type, material compatibility, pressure ratings, and response time must be considered to minimize operational risk and enhance productivity. The significance of making an informed choice is further balanced against potential downtime costs, which can amount to thousands of dollars per hour in manufacturing environments. A well-chosen pneumatic control valve not only ensures seamless operation but also contributes to system longevity and efficiency.

As industries continue to evolve with advanced technologies, understanding the nuances of pneumatic control valves has never been more essential. Leveraging expert advice and comprehensive data sets will empower businesses to make informed decisions tailored to their specific operational needs, ultimately driving significant returns on investment in pneumatic systems.

Understanding the Basics of Pneumatic Control Valves and Their Applications

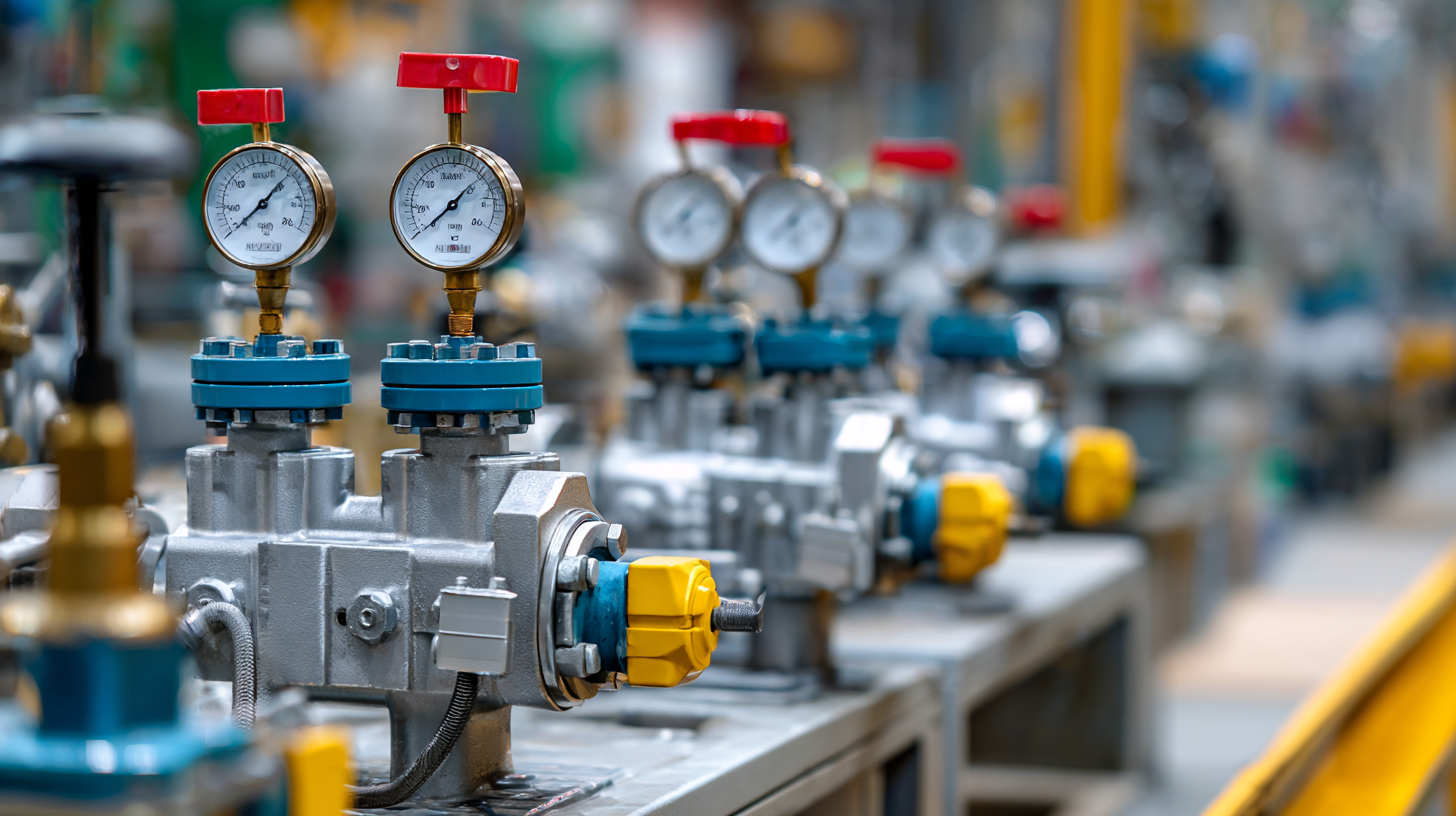

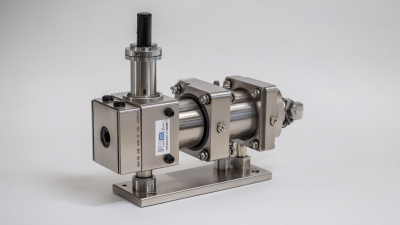

Pneumatic control valves play a crucial role in various industrial applications by regulating the flow and pressure of gases within systems. Understanding the basic components of these valves, such as actuators, positioners, and controllers, is essential for determining their suitability for specific operations. Actuators convert energy into movement, enabling the valve to open or close as required, while positioners ensure accurate valve positioning for precise flow control. Familiarizing oneself with these elements can greatly enhance the efficiency and reliability of pneumatic systems.

Different applications demand different types of pneumatic control valves, including on-off valves, flow control valves, and pressure regulating valves. On-off valves are primarily used in applications where the flow needs to be completely stopped or allowed, whereas flow control valves manage the rate of fluid flow in a system. Pressure regulating valves maintain desired pressure levels, ensuring stable operations in processes such as maintaining proper pressure in conveying systems. By understanding the specific requirements of a given application, operators can select the most appropriate valve type to optimize performance and achieve desired outcomes.

Pneumatic Control Valve Applications

This chart illustrates the percentage distribution of different applications for pneumatic control valves in industrial settings.

Key Factors in Selecting the Right Pneumatic Control Valve for Your Industry

When selecting the right pneumatic control valve for your industry, several key factors must be considered to ensure optimal performance and efficiency. Firstly, understanding the specific application requirements is crucial. This includes assessing the fluid type, operating pressure, and flow rates. Different industries may require valves that can handle varying temperatures and corrosive substances, thus knowing the medium being controlled can guide the choice of materials and construction of the valve.

Another important consideration is the valve’s actuation method. Pneumatic valves can be actuated in various ways, such as electrically, mechanically, or manually. The chosen method should align with the operational needs of the system, including response time and automation level. Additionally, evaluating the valve size and port configurations is essential, as improper sizing may lead to inefficiencies in flow and control. Ultimately, these factors work together to determine the reliability and effectiveness of the pneumatic control valve in meeting industrial demands.

Top 5 Pneumatic Control Valve Brands of 2025: Features and Innovations

When selecting a pneumatic control valve, it's crucial to consider not just the technical specifications, but also the brand's reputation for innovation and reliability. As of 2025, several brands stand out in the market due to their unique features and advancements.

Among these, Brand A is leading with its smart valve technology, which integrates IoT for real-time performance monitoring. This feature enhances efficiency and reduces downtime by allowing for predictive maintenance.

Among these, Brand A is leading with its smart valve technology, which integrates IoT for real-time performance monitoring. This feature enhances efficiency and reduces downtime by allowing for predictive maintenance.

Brand B is known for its lightweight materials, which provide excellent durability without compromising performance. Their focus on energy efficiency is evident through valves designed to minimize air consumption while maximizing flow rates.

In addition, Brand C distinguishes itself by offering customizable options, enabling industries to tailor valves to specific applications, thus improving process control and flexibility. These advancements not only address the varying industrial needs but also set a benchmark for quality and innovation in pneumatic control systems for the future.

Common Mistakes to Avoid When Choosing Pneumatic Control Valves

When selecting pneumatic control valves for industrial applications, one of the most significant pitfalls is underestimating the importance of compatibility with existing systems. Many users focus solely on the specifications of the valve itself, such as size and pressure ratings, without considering how well the valve will integrate with other components. This oversight can lead to performance issues, inefficiencies, and increased costs due to the need for retrofitting or replacing incompatible parts.

Another common mistake is neglecting to consider the specific requirements of the application, such as flow rates and operating temperatures. Failing to evaluate these factors can result in choosing a valve that is either over-sized, leading to wasted resources, or under-sized, which can cause inadequate performance during operation. Additionally, it’s essential to engage with manufacturers or suppliers to gain insights into the best practices for valve selection tailored to specific industrial needs. This proactive approach ensures that the chosen valve not only meets technical specifications but also performs reliably within the intended environment.

How to Choose the Right Pneumatic Control Valve for Your Industrial Needs - Common Mistakes to Avoid When Choosing Pneumatic Control Valves

| Dimension | Criteria | Common Mistakes |

|---|---|---|

| Control Type | Identify if a on/off or modulating valve is needed | Choosing a valve based on convenience rather than application |

| Flow Rate | Ensure valve can handle the application's required flow | Ignoring flow rate specifications |

| Pressure Rating | Select valves that match or exceed system pressures | Selecting valves with insufficient pressure ratings |

| Material Compatibility | Consider materials used in the valve in relation to the media | Using incompatible materials leading to premature failure |

| Size | Ensure the size of the valve fits the piping system | Overlooking the size can cause installation issues |

| Environmental Conditions | Assess conditions such as temperature and humidity | Ignoring environmental factors leading to malfunction |

Maintenance Tips for Ensuring Longevity of Your Industrial Pneumatic Valves

When it comes to industrial pneumatic valves, regular maintenance is crucial for ensuring their longevity and optimal performance. One of the key tips for maintaining these valves is to conduct routine inspections. Checking for any signs of wear and tear, such as leaks or corrosion, allows for early detection of potential issues. Implementing a schedule for these inspections can help prevent unexpected failures and extend the lifespan of the valves.

Additionally, proper lubrication is essential in maintaining the functionality of pneumatic control valves. Using the manufacturer-recommended lubricants can reduce friction and wear on moving parts, which ultimately leads to smoother operation. It's also important to ensure that the valves are kept clean, as dust and debris can impact their performance. Regular cleaning protocols, along with attention to the airflow and pressure settings, will help in maintaining the efficiency and reliability of your pneumatic system, ensuring a longer service life for your equipment.

Related Posts

-

What Makes a Pneumatic Ball Valve the Best Choice for Industrial Applications

-

7 Essential Benefits of Using High Pressure Ball Valves in Industrial Applications

-

Top Strategies for Enhancing Efficiency with Pneumatic Valves in Industrial Applications

-

Understanding the Importance of Flow Control Valves in Modern Engineering Systems

-

Innovative Technologies Shaping the Future of Best Pneumatic Ball Valve Solutions and Strategies for Global Procurement

-

Understanding the Mechanism Behind Ball Check Valves