How to Choose the Best Motorized Valve for Your Industrial Needs

In today's industrial landscape, the choice of a motorized valve is crucial for ensuring efficiency and reliability in fluid control processes. As reported by Research and Markets, the global motorized valve market is expected to reach $25.8 billion by 2027, growing at a CAGR of 6.7% from 2020 to 2027, driven by increased demand in sectors such as oil and gas, water treatment, and chemicals.

The right motorized valve not only improves operational performance but also enhances safety and reduces maintenance costs. This surge in demand highlights the importance of selecting valves that align with specific industrial needs, considering factors such as material compatibility, pressure ratings, and automation features. In this blog, we will explore key considerations and best practices for choosing the ideal motorized valve to optimize your industrial operations, ensuring that your systems are both robust and efficient in a competitive global market.

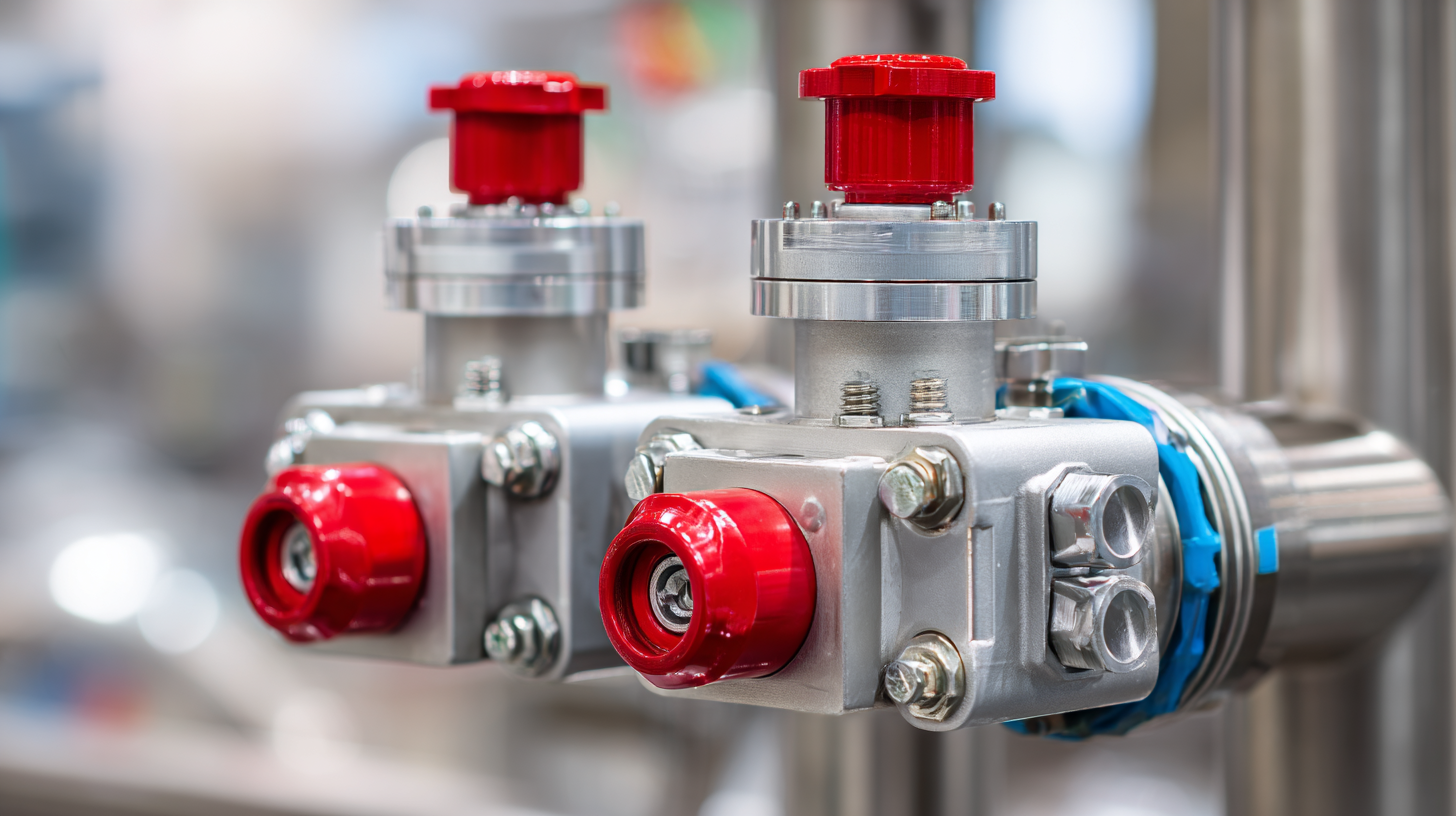

Understanding Motorized Valves: Types and Applications in Industry

Motorized valves play a crucial role in various industrial applications, facilitating the controlled flow of fluids and gases. There are several types of motorized valves, each suited for specific uses. For instance, ball valves offer reliable sealing and can handle high pressures, making them ideal for applications involving liquids and gases under pressure. On the other hand, butterfly valves are often used in large-scale systems because of their lightweight design and ability to regulate flow with precision.

Understanding the specific needs of your application is vital when choosing the right motorized valve. Factors such as the type of fluid being controlled, temperature, pressure, and required flow rate will influence the decision. In environments where space is limited, compact valves like solenoid valves might be more beneficial, while larger systems could leverage actuated gate valves for robust flow control. Ultimately, selecting the best motorized valve hinges on a thorough understanding of these types and their applicable contexts within the broader scope of industry operations.

Key Considerations When Selecting Motorized Valves for Specific Tasks

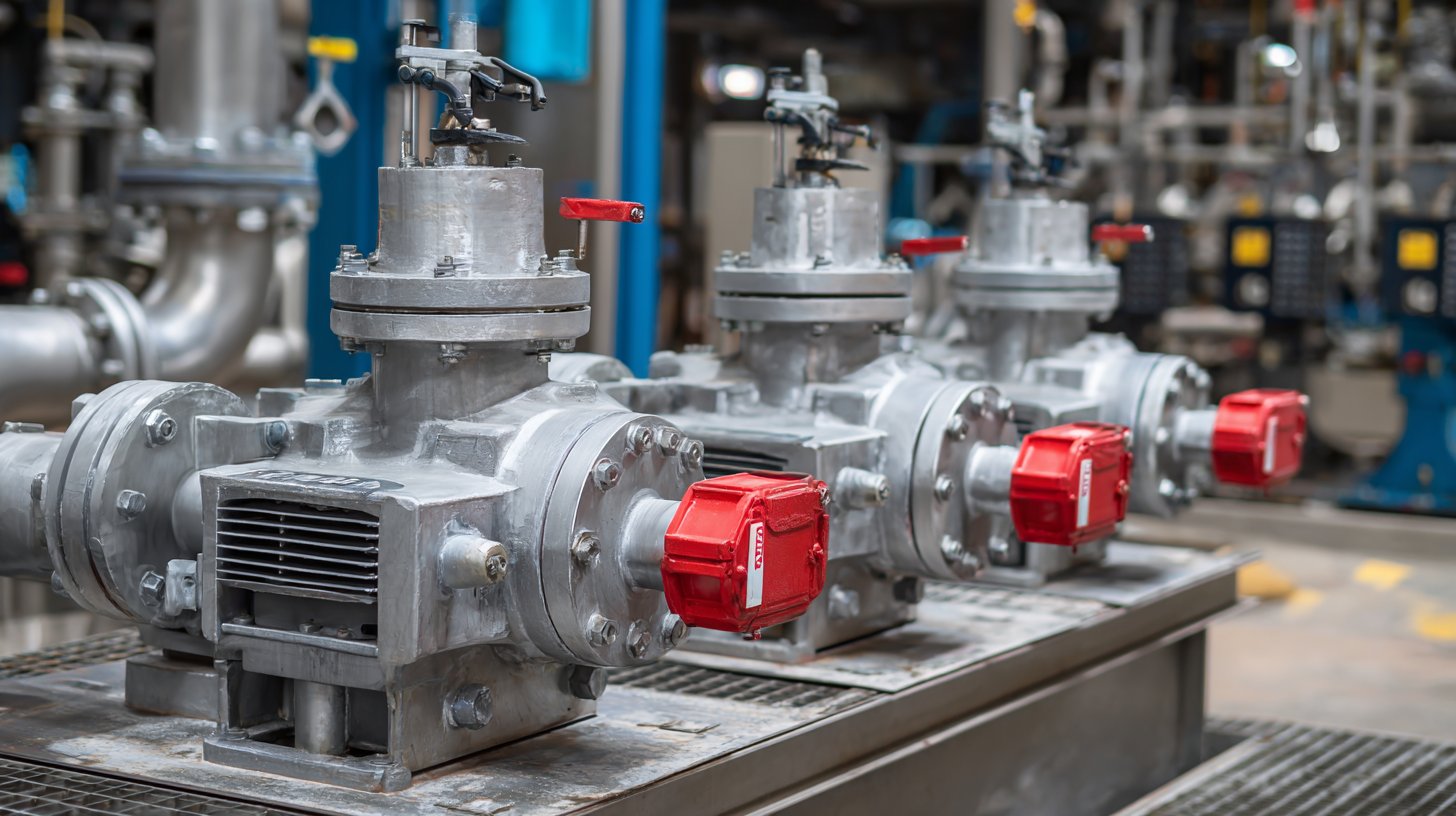

When selecting a motorized valve for industrial applications, it’s crucial to consider the specific requirements of your tasks. Different processes demand different valve types, and understanding the nature of the operation can greatly influence performance and efficiency. For instance, high-pressure systems may require **robust valves** that can withstand intense conditions, while **corrosive environments** dictate the use of materials that resist damage.

When selecting a motorized valve for industrial applications, it’s crucial to consider the specific requirements of your tasks. Different processes demand different valve types, and understanding the nature of the operation can greatly influence performance and efficiency. For instance, high-pressure systems may require **robust valves** that can withstand intense conditions, while **corrosive environments** dictate the use of materials that resist damage.

Tip: Always assess the medium being controlled—whether it’s water, gas, or a chemical. This will help determine the material needed for the valve, ensuring longevity and reliability. Additionally, consider the valve's flow characteristics; a valve with a quarter-turn operation might be ideal for quick shut-off applications, whereas a globe valve might be better suited for throttling.

Another key consideration is the power source for the motorized valve. Different setups may require AC or DC power, and it's advisable to choose one that aligns with your current electrical infrastructure. Tip: Evaluate the available space and layout to ensure there’s adequate room for installation and maintenance. This foresight can prevent operational hiccups and enhance serviceability, ensuring your system remains efficient and effective.

Evaluating Quality Standards: How Chinese Manufacturing Sets the Bar

Chinese manufacturing has become a leading force in the production of motorized valves, setting a high standard for quality and innovation. When evaluating these products, it is crucial to consider various quality certifications, such as ISO and CE marks, which confirm adherence to international safety and quality protocols. These standards ensure that the valves are designed for durability and efficiency, making them a reliable choice for industrial applications.

Tips: Always verify the manufacturer’s commitment to quality control by researching their production processes and materials. Look for companies that employ rigorous testing procedures to ensure that their valves can withstand demanding operational conditions.

Another aspect to consider is the technological advancements implemented in the manufacturing process. Many Chinese manufacturers have integrated automation and precision engineering, enhancing the performance and lifespan of motorized valves. This focus on innovation allows for better energy efficiency and reduced maintenance costs, making these products even more appealing for industrial use.

Tips: Evaluate the specific features that cater to your operational requirements, such as response time and control accuracy. Choosing a valve that aligns with your system requirements can greatly enhance overall efficiency and productivity.

Motorized Valve Quality Evaluation

Maintenance and Troubleshooting Tips for Motorized Valve Performance

When it comes to maintaining the performance of motorized valves in industrial applications, regular inspection and troubleshooting are crucial steps to ensure longevity and efficiency. One essential aspect of maintenance is to check for any signs of wear and tear, such as leaks or irregular operation. It is advisable to create a routine inspection schedule to monitor valve conditions, including the actuator performance and wiring integrity. Ensuring that the valve assembly is clean and free from debris can significantly impact its operational efficiency.

In addition to preventative measures, it is vital to equip maintenance teams with the knowledge to troubleshoot common issues. If a motorized valve fails to open or close properly, it could be a result of inadequate power supply or a malfunctioning actuator. Using diagnostic tools to analyze the valve’s electrical components can help isolate the problem quickly. Moreover, providing training to staff on recognizing warning signs, like unusual noises or slow response times, can enhance the overall reliability of the system. Effective maintenance practices not only prolong the life of motorized valves but also assure safe and optimal performance in demanding industrial environments.

Comparing Cost Efficiency: Investing in Durable vs. Cheap Motorized Valves

When selecting a motorized valve for industrial applications, cost efficiency becomes a pivotal factor. It is essential to analyze the long-term benefits of investing in d durable motorized valves versus opting for cheaper alternatives. While budget-friendly valves may appear attractive initially, their potential for higher failure rates and maintenance costs can ultimately outweigh upfront savings. Durability not only ensures a longer lifespan but also reduces the frequency of replacements, making it a crucial consideration in the context of sustainable practices.

In line with the demands for energy efficiency and environmental sustainability, investing in high-quality motorized valves aligns with broader trends in energy storage and management technologies. Effective industrial processes require reliable components, particularly as companies look to integrate renewable energy systems into their operations. High-quality motorized valves effectively support the seamless operation of these systems, minimizing energy loss and improving overall efficiency. By prioritizing durability, industries can not only achieve better operational outcomes but also contribute positively to environmental goals, reinforcing the overall economic and ecological benefits of sustainable technology investments.