How to Choose the Right Stainless Steel Ball Valve for Your Needs

Selecting the right stainless steel ball valve is crucial for ensuring the efficiency and longevity of various applications in piping systems. These valves are widely favored in industries such as water treatment, oil and gas, chemical processing, and food production due to their excellent corrosion resistance, durability, and ease of operation. However, with a plethora of options available, making the right choice can be a daunting task.

Understanding the specific requirements of your project is the first step in choosing the appropriate stainless steel ball valve. Factors such as the media being transported, pressure and temperature conditions, and connection types all play a vital role in the selection process. Additionally, considerations regarding maintenance requirements and the anticipated life cycle of the valve can further refine your choices. By taking the time to assess these elements, you can ensure that the stainless steel ball valve you select will perform optimally throughout its intended use, leading to improved operational reliability and cost-effectiveness.

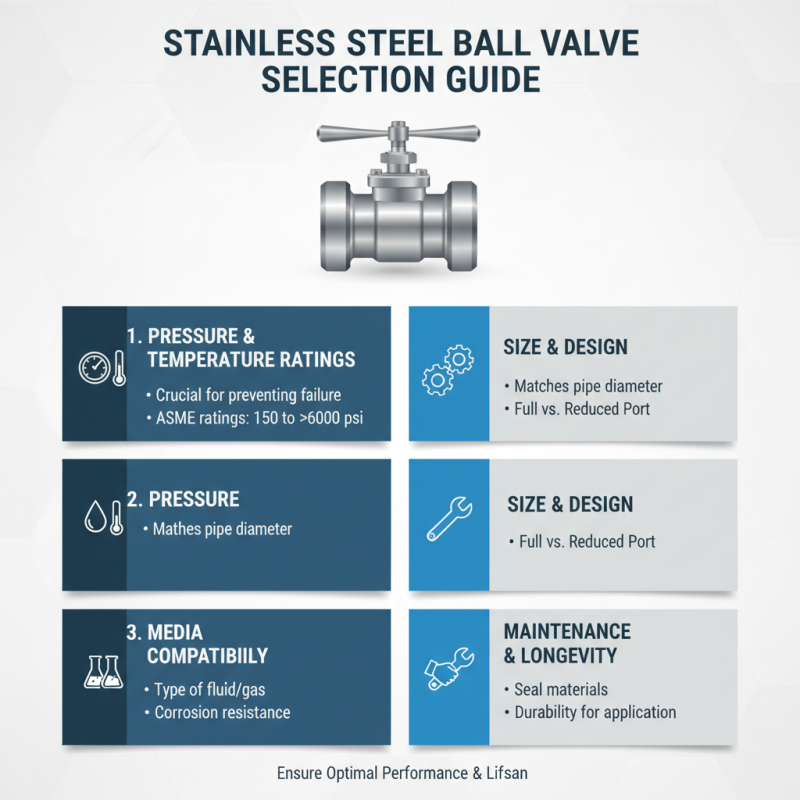

Factors to Consider When Selecting a Stainless Steel Ball Valve

When selecting a stainless steel ball valve, several crucial factors must be considered to ensure optimal performance and longevity. First and foremost, evaluate the valve's pressure and temperature ratings. According to the American Society of Mechanical Engineers (ASME), stainless steel ball valves typically have maximum pressure ratings ranging from 150 psi to over 6000 psi, depending on the size and design. It's vital to choose a valve that can handle the specific pressure and temperature conditions of your application to prevent premature failure.

Another significant factor is the valve's size and end connection type. Proper sizing is essential for ensuring effective flow control and avoiding unnecessary pressure drops. The National Fluid Power Association (NFPA) suggests mindful consideration of the flow rate requirements and the compatibility of the valve with the piping system. Additionally, end connection types such as threaded, flanged, or welded should align with the existing infrastructure to facilitate easier installation and maintenance.

Tips: Always consult with a professional engineer when determining the specifications for your stainless steel ball valve. They can provide insights based on industry standards and best practices. It’s also wise to conduct regular inspections and maintenance of your valves to ensure they remain in peak operating condition, potentially extending their lifespan and enhancing system reliability.

Understanding Valve Types: Two-Way vs. Three-Way Ball Valves

When selecting the right stainless steel ball valve, understanding the differences between two-way and three-way configurations is crucial. Two-way ball valves are primarily used to control the flow of liquids or gases in a straightforward on/off mode, allowing for a simple and direct path in piping systems. According to a report from the Global Ball Valve Market, two-way valves account for a significant portion—approximately 60%—of the overall demand due to their efficiency and ease of use in applications ranging from HVAC systems to water supply pipelines.

On the other hand, three-way ball valves offer more versatility by allowing flow control from multiple sources or to multiple destinations. They are designed to mix or separate fluids, making them essential in applications requiring flow diversion or blending. The versatility of three-way valves has increased their adoption, with estimates suggesting they comprise around 30% of the market share. Industries such as chemical processing and food & beverage often utilize these valves due to their ability to manage complex flow patterns. Thus, understanding these valve types not only aids in selecting the right one for your needs but also ensures optimized performance in operational efficiency.

How to Choose the Right Stainless Steel Ball Valve for Your Needs

| Valve Type | Configuration | Applications | Advantages | Temperature Range (°F) | Pressure Rating (PSI) |

|---|---|---|---|---|---|

| Two-Way Ball Valve | 1 Inlet, 1 Outlet | Water, Gas, Oil | Simple Operation, Compact Design | -20 to 350 | 1500 |

| Three-Way Ball Valve | 1 Inlet, 2 Outlets | Diverse Flow Control | Versatile Applications | -20 to 300 | 1200 |

| Floating Ball Valve | Standard Design | General Use | Cost-Effective, Easy Maintenance | -20 to 210 | 600 |

| Trunnion Ball Valve | Fixed Ball Design | High-Pressure Systems | Stability, Large Diameter | -20 to 400 | 3000 |

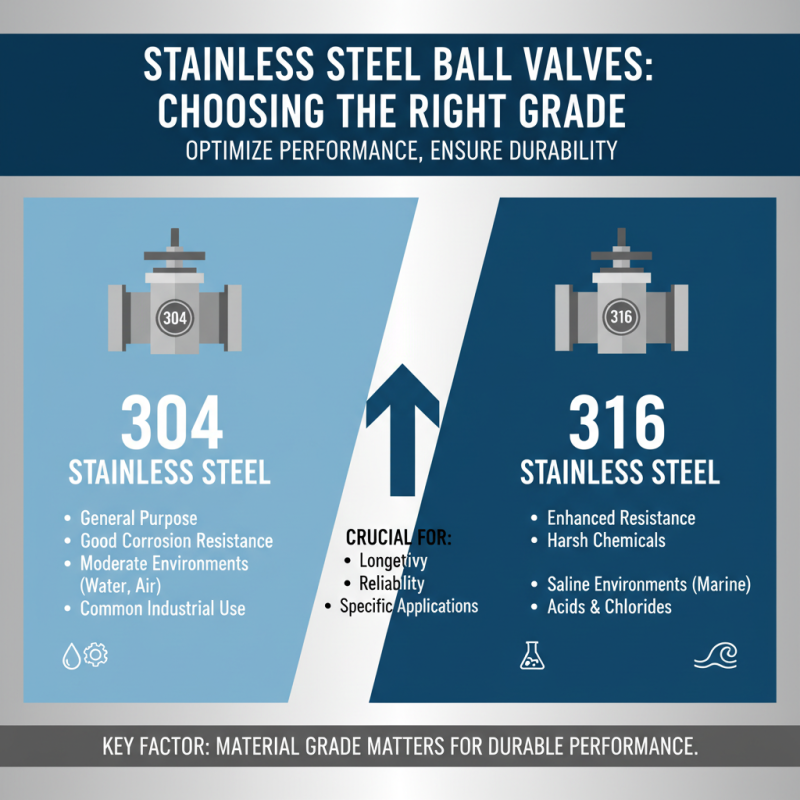

The Importance of Material Grades in Stainless Steel Ball Valves

Choosing the right stainless steel ball valve is crucial for ensuring long-lasting performance in various industrial applications. Understanding the importance of material grades in stainless steel ball valves can significantly influence your decision. Stainless steel is categorized into different grades, each providing unique properties and resistance to environmental factors. For instance, 304 stainless steel is commonly used for its good corrosion resistance in moderate environments, while 316 stainless steel offers enhanced protection against harsh chemicals and saline conditions.

When selecting a stainless steel ball valve, it's essential to consider the specific requirements of your application. Factors such as temperature, pressure, and the type of fluid being transported should guide your choice of material grade. Higher-grade materials tend to have better durability and longevity, which can lead to reduced maintenance costs and improved operational efficiency. By investing in the appropriate stainless steel grade for your ball valve, you not only ensure reliable performance but also enhance the overall safety and efficacy of your piping system.

Sizing and Flow Requirements for Optimal Valve Performance

When selecting a stainless steel ball valve, understanding sizing and flow requirements is crucial for ensuring optimal valve performance. The size of the valve must align with the piping system to prevent flow restrictions or pressure drops. A properly sized valve facilitates adequate fluid movement and minimizes wear, therefore extending the valve's lifespan. It is important to consider the nominal pipe size (NPS) and the corresponding valve diameter to achieve the desired flow rates in your application.

In addition to sizing, flow requirements, such as the fluid type, temperature, and pressure, must be taken into account. High flow rates may necessitate a larger valve to maintain efficiency, while applications involving viscous fluids may require a valve designed for restricted flow to promote proper mixing.

A proper understanding of these parameters helps in selecting a valve that not only meets the mechanical specifications but also enhances overall system performance. By focusing on these factors, users can ensure that the chosen valve operates efficiently within their particular application context.

Maintenance and Longevity Considerations for Stainless Steel Ball Valves

When selecting stainless steel ball valves, maintenance and longevity are crucial factors that can significantly impact performance and cost-effectiveness. According to industry reports, regular maintenance can enhance the lifespan of these valves by 20-30%. Proper upkeep includes routine inspection for leaks, corrosion, and buildup of debris, as even minor issues can lead to more significant failures if left unattended. Ensuring that the valve operates within its specified pressure and temperature ranges also contributes to its longevity, preventing premature wear.

Tip: Implement a scheduled maintenance program to regularly check and maintain your stainless steel ball valves. This preventive approach often results in fewer unexpected breakdowns and can save on replacement costs.

Another important consideration is the material quality of the ball valve. High-quality stainless steel grades, such as 316, offer superior resistance to corrosion and temperature fluctuations, which are critical for maintaining functionality in harsh environments. A recent study revealed that using premium materials can extend the operational life of a valve from an average of 5 years to over 10 years when properly maintained.

Tip: When selecting stainless steel ball valves, always inquire about the material specifications and consider investing in valves that meet higher industry standards to maximize durability.

Related Posts

-

The Ultimate Guide to Choosing the Right Stainless Steel Ball Valve for Your Industrial Needs

-

Mastering the Basics of 3 Way Ball Valve Installation and Maintenance Guide

-

7 Essential Benefits of Using High Pressure Ball Valves in Industrial Applications

-

Global Excellence in Control Valve Manufacturing China Leads the Way

-

What Makes the Best PVC Ball Valve Ideal for Your Business Needs

-

Discover Top Quality Electric Valves from Leading Manufacturers in China