How to Choose the Right Ball Check Valve for Your Industrial Needs

Choosing the right ball check valve for industrial applications is a critical decision that can significantly impact the efficiency and safety of your operations. A ball check valve is designed to allow fluid flow in one direction while preventing backflow, making it essential in various systems where maintaining a unidirectional flow is crucial. With numerous options available on the market, understanding the specific needs of your application is vital. This guide will explore key factors to consider when selecting a ball check valve, including material compatibility, pressure ratings, and installation requirements. By taking the time to evaluate these aspects, you can ensure that your chosen ball check valve meets the demands of your industrial environment, ultimately leading to enhanced performance and reliability.

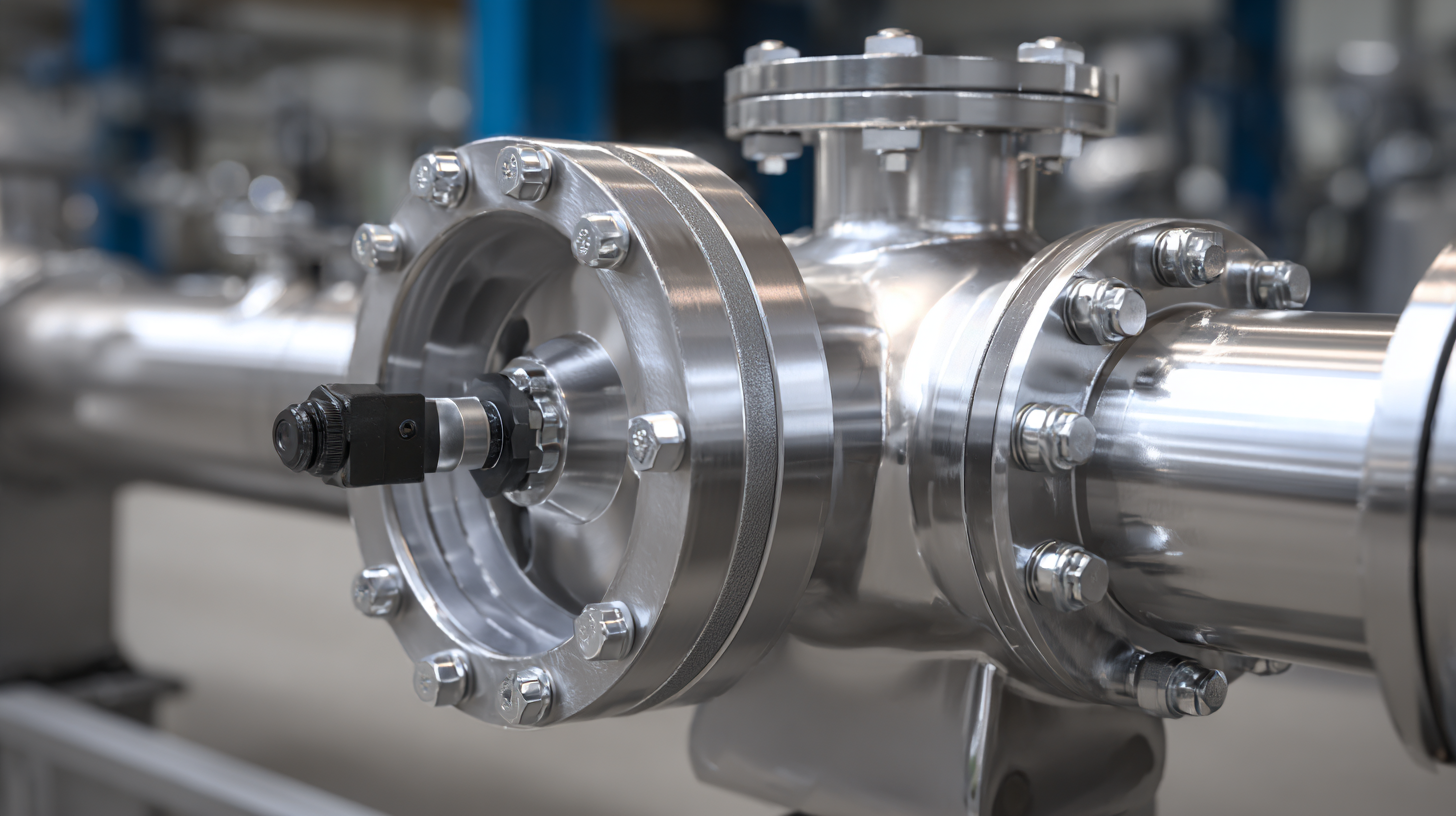

Understanding the Functionality of Ball Check Valves in Industrial Applications

Ball check valves play a crucial role in various industrial applications by ensuring that the flow of liquids and gases only moves in one direction. These devices utilize a spherical ball that fits snugly into a valve seat, preventing backflow and maintaining system integrity. In industries such as oil and gas, water treatment, and chemical manufacturing, the reliability of ball check valves is paramount. According to a recent report by Markets and Markets, the global check valves market is expected to grow from $3.1 billion in 2022 to $4.2 billion by 2027, driven by the increasing demand for efficient fluid management systems.

Ball check valves play a crucial role in various industrial applications by ensuring that the flow of liquids and gases only moves in one direction. These devices utilize a spherical ball that fits snugly into a valve seat, preventing backflow and maintaining system integrity. In industries such as oil and gas, water treatment, and chemical manufacturing, the reliability of ball check valves is paramount. According to a recent report by Markets and Markets, the global check valves market is expected to grow from $3.1 billion in 2022 to $4.2 billion by 2027, driven by the increasing demand for efficient fluid management systems.

When choosing the right ball check valve, consider factors such as the fluid's characteristics, pressure ratings, and installation environment. For instance, high viscosity fluids may require larger valve sizes to mitigate flow resistance. Additionally, temperature tolerance is essential; materials like PVC may not withstand high temperatures compared to metal options.

Tips: Always consult the manufacturer’s specifications for pressure drop and flow rates to ensure compatibility with your system. Regular maintenance checks can also help in identifying wear or obstruction that could compromise valve functionality. Lastly, seek professional guidance or refer to industry standards when in doubt about selection criteria.

Key Factors to Consider When Selecting Ball Check Valves for Specific Systems

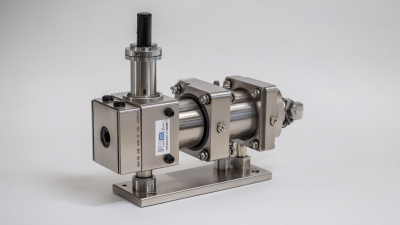

When selecting a ball check valve for industrial applications, there are several key factors to consider to ensure optimal performance and compatibility with specific systems. Firstly, understanding the fluid characteristics is crucial. This includes analyzing the fluid's viscosity, temperature, and corrosiveness, which will influence the choice of materials used in the valve’s construction. For instance, corrosive fluids may require valves made from stainless steel or other resistant alloys to prolong lifespan and maintain functionality.

Another critical aspect is the valve sizing and flow rate requirements. Proper sizing ensures that the valve effectively prevents backflow without obstructing the intended flow in the system. It is essential to calculate the required flow rate and select a valve that matches these specifications. Additionally, considering the installation environment, including factors such as pressure ratings, available space, and accessibility for maintenance, will impact the selection process. By addressing these considerations, you can make an informed choice that enhances system reliability and efficiency.

Ball Check Valve Selection Criteria

Material Selection: The Impact of Corrosion Resistance on Valve Longevity

When selecting a ball check valve for industrial applications, material selection is critical, particularly concerning corrosion resistance. The longevity of a valve largely depends on the materials used in its construction, as exposure to harsh environments can lead to premature failure. Stainless steel, for instance, is favored in many industries due to its excellent resistance to rust and corrosive substances. However, in extreme conditions, more specialized materials like polyvinylidene fluoride (PVDF) or Hastelloy may be required to ensure optimal performance.

**Tips:**

1. Evaluate the specific chemicals and environmental conditions the valve will encounter. This analysis will help you choose a material that can withstand potential corrosion and wear.

2. Consider the temperature and pressure ratings of the materials, as these factors can significantly influence a valve's lifespan and effectiveness.

Additionally, it’s important to assess the manufacturing standards and certifications of the valve you intend to purchase. Valves that comply with industry standards not only offer reliability but also ensure greater resistance to corrosive elements. By prioritizing material selection and understanding the implications of corrosion resistance, you can secure a durable and effective ball check valve that meets your industrial needs.

How to Choose the Right Ball Check Valve for Your Industrial Needs - Material Selection: The Impact of Corrosion Resistance on Valve Longevity

| Material | Corrosion Resistance | Temperature Range (°C) | Pressure Rating (PSI) | Longevity (Years) |

|---|---|---|---|---|

| Stainless Steel 304 | Good | -50 to 400 | 150 | 10 |

| Stainless Steel 316 | Excellent | -50 to 450 | 150 | 15 |

| Brass | Moderate | -20 to 200 | 120 | 8 |

| PVC | Fair | 0 to 60 | 40 | 5 |

| Ductile Iron | Good | -20 to 150 | 200 | 12 |

Flow Characteristics: Optimizing Efficiency with Proper Size and Design

When selecting a ball check valve for industrial applications, understanding the flow characteristics is crucial for optimizing efficiency. According to the 2021 Flow Control Industry Report, improper sizing of valves can lead to energy losses upwards of 20%. This highlights the importance of matching the valve size and design to the specific requirements of the system, as flow dynamics can significantly impact overall operational costs.

A well-designed ball check valve minimizes pressure drop and enhances flow rate. The American Society of Mechanical Engineers (ASME) recommends a size selection methodology that considers the pipeline's fluid type, temperature, and pressure conditions. Additionally, valve designs that feature smooth surfaces and streamlined profiles can reduce turbulence, further enhancing flow efficiency. This is particularly critical in industries such as oil and gas, where the cost of inefficiencies can be substantial. Ensuring that the valve is appropriately sized not only bolsters performance but can also prolong equipment life, reducing maintenance costs and downtime.

Maintenance Requirements: Ensuring Reliability and Performance in Operation

When selecting a ball check valve for industrial applications, maintenance requirements play a crucial role in ensuring reliability and performance during operation. Regular maintenance of these valves can prevent unexpected failures and prolong their lifespan. Key practices include routine inspections to check for wear and tear, leaks, or blockages that can impede functionality. Additionally, cleaning the internal components regularly helps maintain optimal flow and prevents build-up that could lead to operational issues.

Another important aspect of maintenance is ensuring that the valve sealing surfaces are in excellent condition. Over time, the seals can deteriorate, leading to a loss of performance and increased risk of leaks. It is advisable to establish a maintenance schedule that includes replacement of seals based on operational conditions and manufacturer recommendations. Furthermore, ensuring that the ball check valve is installed correctly can minimize maintenance needs and enhance overall durability. By adopting proactive maintenance strategies, industries can maximize the efficiency and reliability of their ball check valves, ultimately supporting smoother operations.

Related Posts

-

Understanding the Mechanism Behind Ball Check Valves

-

7 Effective Strategies for Choosing the Right Electric Valve

-

What Makes a Pneumatic Ball Valve the Best Choice for Industrial Applications

-

What Defines an Actuated Ball Valve and Its Importance in Industrial Applications

-

What Makes the Best PVC Ball Valve Ideal for Your Business Needs

-

Innovative Technologies Shaping the Future of Best Pneumatic Ball Valve Solutions and Strategies for Global Procurement