Top 10 Benefits of Using Ball Check Valves in Industrial Applications

In the realm of industrial applications, the importance of effective fluid management cannot be overstated. One crucial component that has gained recognition for its reliability and efficiency is the ball check valve. According to John H. Smith, a renowned expert in valve technology, "The ball check valve stands out for its simple design and remarkable ability to prevent backflow, making it an essential tool in various industrial processes." This statement encapsulates the core functionality and significance of ball check valves in modern engineering systems.

As industries evolve and the demand for streamlined operations increases, the adoption of ball check valves is becoming ever more prevalent. These valves offer a range of benefits, including enhanced safety, reduced maintenance costs, and improved system efficiency. In this article, we will explore the top 10 advantages of utilizing ball check valves in industrial settings, providing insights into how these innovative devices contribute to more effective and reliable fluid control. By understanding the transformative impact of ball check valves, industries can make informed decisions that enhance both productivity and operational integrity.

Key Advantages of Ball Check Valves in Industrial Systems

Ball check valves are essential components in industrial systems, offering a range of key advantages that enhance operational efficiency and reliability. One of the primary benefits is their ability to prevent backflow, ensuring that fluids flow in the desired direction. This functionality is crucial in various applications, such as water treatment plants and chemical processing, where contamination from reverse flow can lead to significant issues, including damage to equipment and compromised system integrity. Another notable advantage of ball check valves is their low maintenance requirement. Compared to other valve types, ball check valves have a simple design that minimizes wear and tear, reducing the need for frequent replacements and maintenance checks. This not only saves time but also cuts down operational costs, allowing businesses to allocate resources more effectively. Tips: When selecting ball check valves, consider factors such as fluid type, pressure, and temperature to ensure optimal performance. Regular monitoring of the valve's functionality can also help identify potential issues before they escalate, maintaining the integrity of your industrial systems. Additionally, using high-quality materials can enhance durability and performance, leading to longer service life and greater reliability.

How Ball Check Valves Prevent Backflow and Enhance Efficiency

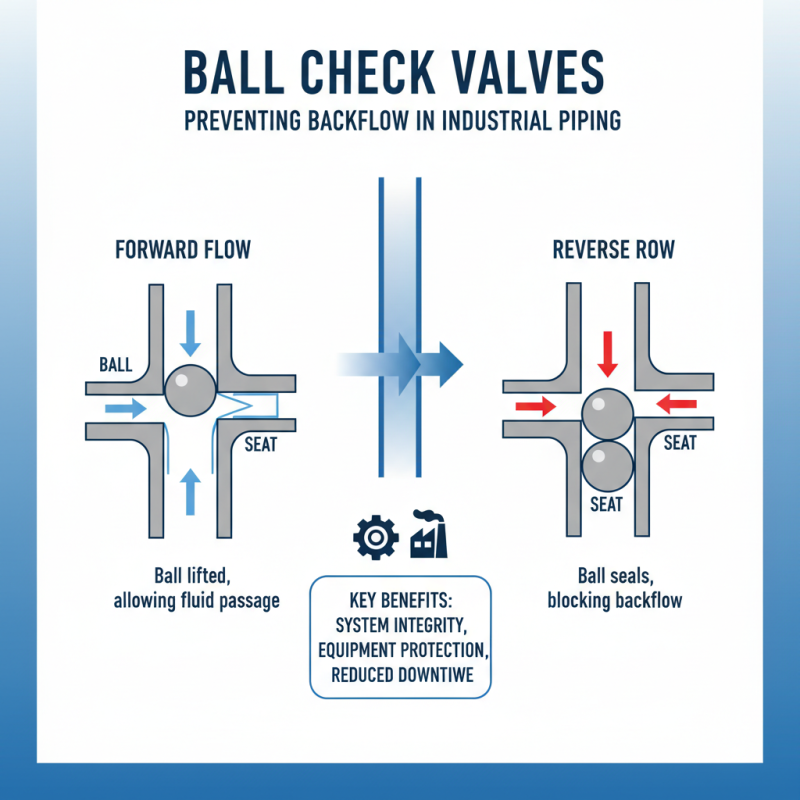

Ball check valves are essential components in industrial applications, designed to prevent backflow in piping systems. These valves operate on a simple yet effective principle: the ball inside the valve moves in response to flow direction. When fluid flows in the intended direction, the ball is pushed off its seat, allowing for smooth passage. Conversely, if there is a reverse flow, the ball seals against its seat, blocking the unwanted backflow. This mechanism is crucial in maintaining system integrity and preventing damage to equipment, which can be costly and time-consuming to repair.

In addition to preventing backflow, ball check valves enhance overall system efficiency. By ensuring that liquids or gases do not flow backward, these valves contribute to a more reliable operation of pumps and other equipment. This not only leads to improved performance but also reduces the risk of cavitation, which can occur if backflow is allowed. Moreover, the low-pressure drop associated with ball check valves minimizes energy consumption, making them an economical choice for various industrial processes. The seamless operation and preventive capabilities of ball check valves underscore their significance in enhancing efficiency and ensuring safety in industrial settings.

Durability and Maintenance Benefits of Ball Check Valves in Industry

Ball check valves are essential components in various industrial applications due to their unique design and functionality. One of the significant benefits is their durability. Constructed from robust materials, these valves can withstand harsh conditions, including extreme temperatures and pressures, which are commonplace in industrial settings. This durability ensures a longer lifespan and fewer replacements, making them a cost-effective choice in the long run.

Maintenance is another essential consideration when using ball check valves. Their design minimizes the risk of obstructions, as the ball mechanism allows for a smoother flow of fluids, reducing wear and tear on the valve itself. Regular inspections are straightforward, as these valves typically do not require elaborate maintenance procedures. This reduces downtime for maintenance and keeps operations running smoothly.

**Tip:** To maximize the lifespan of ball check valves, consider implementing a routine inspection schedule. Look out for signs of wear or debris buildup that could affect performance. Keeping the valves free of contaminants will ensure their continued efficiency and durability.

In addition, always ensure that the installation is performed correctly by trained personnel, as improper installation can lead to premature failure and increased maintenance needs. Adhering to these practices can vastly enhance the reliability of ball check valves in your industrial applications.

Top 10 Benefits of Using Ball Check Valves in Industrial Applications

Cost-Effectiveness of Using Ball Check Valves for Long-Term Operations

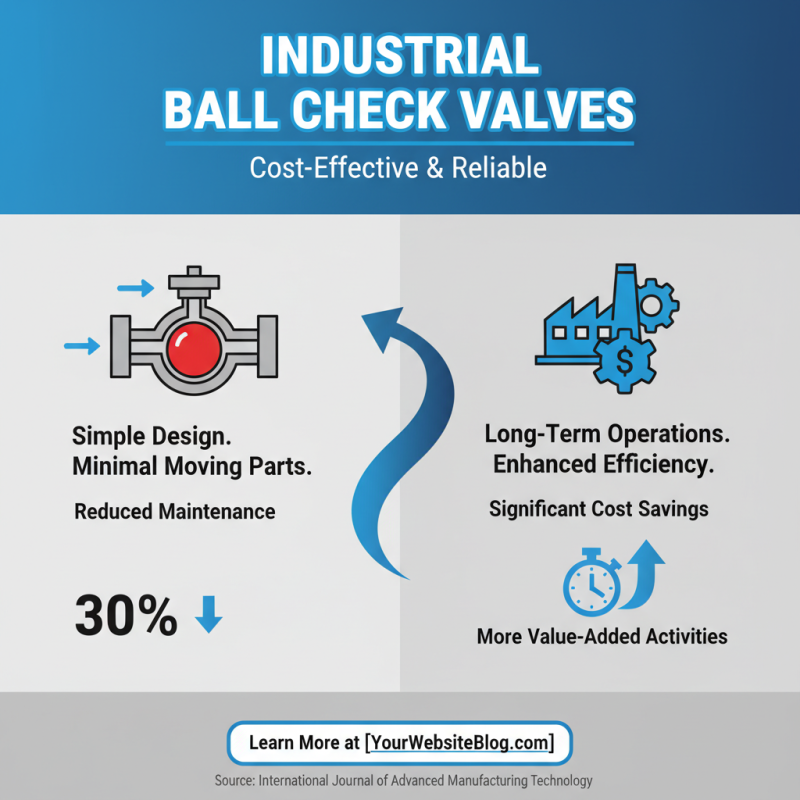

Ball check valves are increasingly favored in industrial applications for their cost-effectiveness and reliability over long-term operations. A study by the International Journal of Advanced Manufacturing Technology indicates that these valves can significantly reduce maintenance costs—by up to 30%—due to their simple design and minimal moving parts. This reduction in maintenance not only saves money but also enhances operational efficiency, allowing companies to allocate resources to more value-added activities.

Moreover, the lifespan of ball check valves plays a crucial role in their cost-effectiveness. According to a report from the American Society of Mechanical Engineers, properly chosen and maintained ball check valves can perform effectively for over 20 years in harsh industrial environments. Their durability translates into lower replacement frequency and, consequently, minimized downtime. Factoring in the initial purchase price, installation costs, and long-term savings, industry experts suggest that using ball check valves can yield an overall 25% reduction in lifetime operational costs compared to traditional check valves. This compelling data makes ball check valves an attractive component of any industrial system, providing both immediate and long-term financial advantages.

Applications and Impact of Ball Check Valves in Various Industries

Ball check valves play a crucial role in various industrial applications, providing reliable and efficient solutions for preventing backflow in piping systems. These valves function by allowing fluid to flow in one direction while instantly blocking reverse flow, which is essential in systems such as wastewater treatment, chemical processing, and water supply management. In industries where contamination risks are high, the design of ball check valves minimizes the chances of fluid mixing, thus ensuring product integrity and safety. Their robust construction makes them suitable for handling different media, from water to corrosive chemicals, and their operational simplicity allows for easy maintenance, further enhancing their appeal.

In the manufacturing sector, ball check valves are instrumental in processes where the accuracy of fluid dynamics is essential. Applications often include hydraulic systems, where any backflow can lead to system failure or inefficiencies. The ease of installation and their ability to maintain consistent flow rates contribute to their effectiveness. Additionally, industries such as food and beverage, where hygiene is paramount, benefit significantly from the non-leak design of ball check valves, which helps maintain cleanliness and compliance with health regulations. As industries continue to evolve and seek more efficient fluid management systems, the impact of ball check valves remains significant, addressing operational challenges while promoting reliability and safety across various applications.

| Benefit | Description | Application Areas | Impact |

|---|---|---|---|

| Prevention of Backflow | Ball check valves prevent the reverse flow of fluids, ensuring system integrity. | Water Treatment, Oil & Gas | Improves system efficiency and safety. |

| Low Maintenance | These valves require minimal upkeep due to their simple design. | Chemical Processing, HVAC | Reduces operational costs over time. |

| Durability | Constructed from robust materials, ensuring longevity. | Mining, Pulp & Paper | Optimizes equipment lifespan and reduces failure rates. |

| Wide Range of Applications | Versatile for various fluids and gas environments. | Food and Beverage, Pharmaceuticals | Enhances adaptability to diverse industrial needs. |

| Cost-Effectiveness | Affordable solution for controlling flow without complex mechanisms. | Agriculture, Waste Management | Improves ROI through lowered installation and maintenance costs. |

| Easy Installation | Designed for quick and straightforward setup. | Construction, HVAC | Reduces downtime and enhances project efficiency. |

| Preventive Flow Control | Regulates flow to prevent system overloads. | Heating Systems, Cooling Systems | Enhances system reliability and performance. |

| Safety | Reduces risk of backpressure and leaks. | Chemical Transport, Oil & Gas | Promotes operator safety and environmental compliance. |

| Efficiency Improvement | Optimizes flow conditions, improving system efficiency. | Pulp & Paper, Water Supply | Enhances productivity across operations. |

Related Posts

-

Mastering the Basics of 3 Way Ball Valve Installation and Maintenance Guide

-

7 Essential Benefits of Using High Pressure Ball Valves in Industrial Applications

-

Understanding the Mechanism Behind Ball Check Valves

-

How to Choose the Right Ball Check Valve for Your Industrial Needs

-

The Ultimate Guide to Choosing the Right Stainless Steel Ball Valve for Your Industrial Needs

-

How to Choose the Right Stainless Steel Ball Valve for Your Needs