2025 Top PVC Ball Valve Types: A Comprehensive Guide to Choosing the Best

When it comes to plumbing and industrial applications, selecting the right valve type is crucial for ensuring optimal performance and longevity. Among the various options available, the PVC ball valve has gained significant popularity due to its versatility, durability, and cost-effectiveness. With advancements in manufacturing techniques and materials, the PVC ball valve has evolved, offering a wide range of features and designs tailored to meet diverse needs. This comprehensive guide highlights the top PVC ball valve types for 2025, assisting you in making an informed decision when selecting the best valve for your specific requirements.

In this guide, we will explore the leading PVC ball valve designs on the market and delve into the factors that contribute to their effectiveness and reliability. Whether you're looking for a valve for residential, commercial, or industrial use, understanding the various types of PVC ball valves will empower you to choose one that aligns with your operational demands. From considerations such as pressure ratings and temperature limits to the benefits of different end connections, this overview aims to shed light on the key characteristics to evaluate when investing in PVC ball valves for your projects. Join us as we discover the top five PVC ball valve types for 2025 and equip yourself with the knowledge needed for a successful selection.

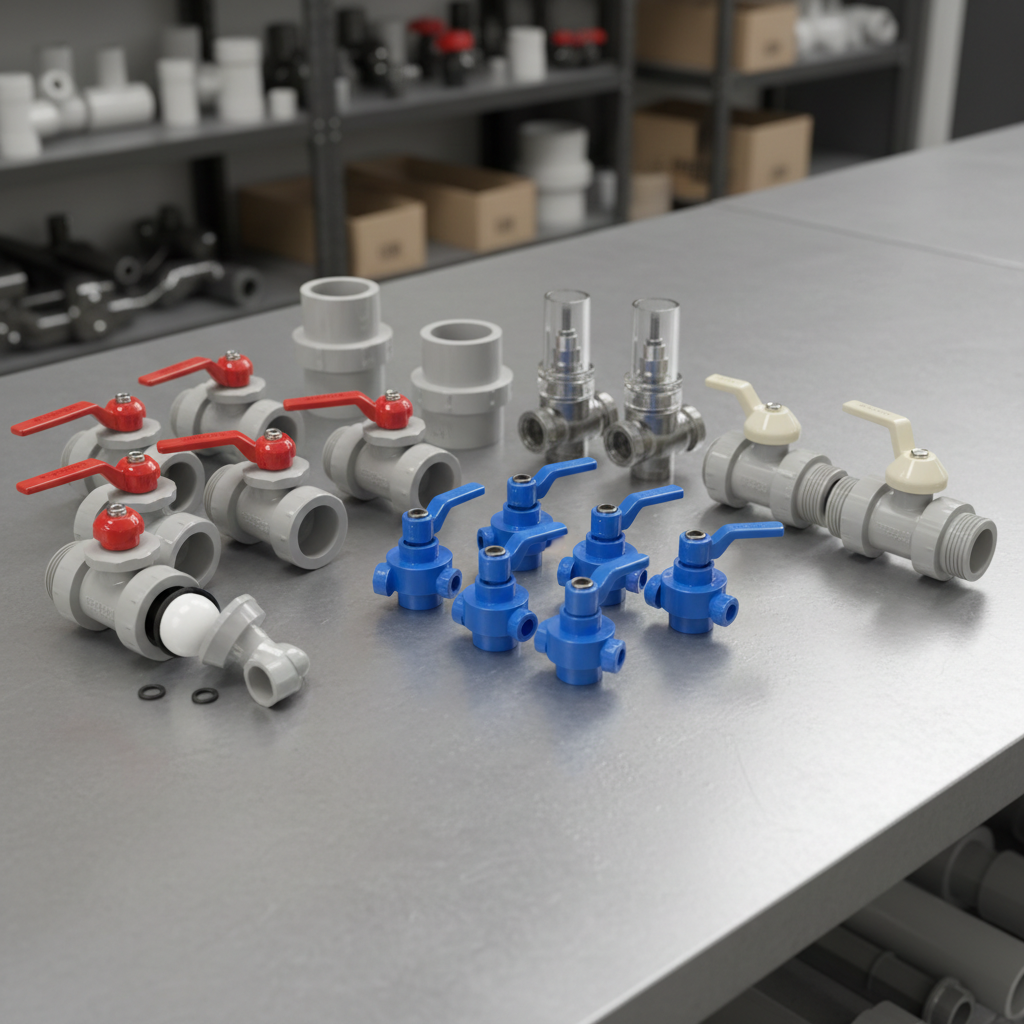

Understanding the Basics of PVC Ball Valve Types

When selecting a PVC ball valve, it’s essential to understand the various types available and their specific applications. PVC ball valves are categorized primarily into two designs: full port and standard port. Full port valves have a larger diameter, allowing for unobstructed flow, making them ideal for systems requiring minimal pressure drop. In contrast, standard port valves have a smaller opening, which can lead to increased turbulence but may be suitable for less demanding applications.

Another important factor to consider is the valve's construction material. While PVC is a popular choice for its durability and resistance to corrosion, there are variations such as CPVC and Geo-Polymer PVC that are designed to withstand higher temperatures or aggressive chemicals. Additionally, the valve's actuator type—manual, electric, or pneumatic—plays a crucial role in its usability and efficiency in various systems. Understanding these basics equips you to make informed decisions when choosing the best PVC ball valve for your needs.

Key Features to Consider When Selecting PVC Ball Valves

When selecting the best PVC ball valves in 2025, several key features should be taken into account to ensure optimal performance and longevity. One of the primary factors is the material quality of the valve. High-grade PVC is crucial for resistance to corrosion and chemical damage, especially in applications involving aggressive fluids. Additionally, consider the pressure rating of the valve; it must align with the demands of your specific system to prevent leaks and failures.

Another vital aspect is the valve design, which includes the ball and seat construction. Look for valves that feature a full-port design, as they allow for maximum flow and reduced turbulence. Additionally, the ease of operation is significant. Valves with ergonomic handles and smooth rotation can contribute to efficient system management. Finally, ensure that the valve you choose complies with relevant industry standards, as this guarantees reliability and safety in its intended applications. Taking these features into consideration will lead to a more informed purchase and increased system efficiency.

Comparing Different PVC Ball Valve Designs

When selecting the best PVC ball valve for your application, understanding the various designs available is crucial. PVC ball valves are primarily categorized into three types:

full port,

standard port, and

reduced port.

Full port valves allow for the maximum flow of fluid with minimal pressure drop, making them ideal for high-flow applications, while standard port valves offer a balance between performance and cost.

According to a report by the Global PVC Valves Market Analysis, the demand for full port designs is expected to rise by 15% by 2025 due to their efficiency in handling viscous fluids.

Another essential aspect to consider is the valve's end connections. PVC ball valves can come with different types of fittings such as

threaded,

socket, or

flanged ends.

A recent study from the Plumber's Supply Association highlighted that socket fittings are preferred in residential applications due to their leak-proof capabilities, whereas threaded ends are often used in industrial settings for ease of assembly and disassembly. Understanding the specific requirements of your project will guide you in selecting the appropriate valve design that not only meets operational criteria but also adheres to industry standards for safety and reliability.

Common Applications for Each Type of PVC Ball Valve

When selecting the right PVC ball valve for your application, it is essential to consider the specific requirements of each type. Standard PVC ball valves are commonly used in irrigation systems and residential plumbing due to their corrosion resistance and affordability. These valves can operate at low to moderate pressures, making them ideal for controlling water flow in agricultural settings and home water supply systems.

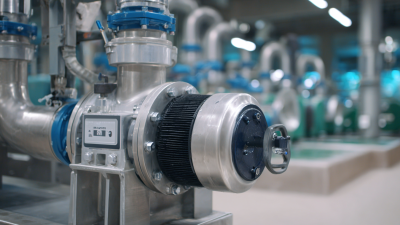

For applications requiring higher durability and temperature tolerance, reinforced PVC ball valves are preferred. These valves are often employed in industrial settings, such as chemical processing and wastewater treatment facilities. Their enhanced strength allows them to handle aggressive chemicals and higher flow rates without compromising performance.

Additionally, specialty PVC ball valves, like those with a full port design, are beneficial in applications that demand minimal fluid resistance, such as in aquariums and hydroponics systems. By understanding the unique attributes and common applications of each type, users can make informed decisions tailored to their operational needs.

Maintenance Tips for Long-Lasting PVC Ball Valves

Proper maintenance of PVC ball valves is crucial to ensure their longevity and efficiency. According to a recent industry report by the Plastics Pipe Institute, well-maintained PVC valves can last up to 50% longer than poorly maintained ones. Regular inspections can identify wear and tear that, if left unaddressed, could lead to leaks or malfunctions. One essential tip is to regularly check for signs of corrosion, as even slight degradation can affect performance.

In addition, lubricating the valve's moving parts with a compatible lubricant can significantly enhance operation and prevent sticking. It's recommended to perform this maintenance every six months to a year, depending on usage. A study from the Valve Manufacturers Association indicates that effective lubrication can reduce wear and friction by up to 30%, optimizing the valve's function over its service life.

Lastly, ensure that the pipes connected to the ball valves are not under excessive stress, as misalignment can lead to premature failure. Investing time in these maintenance practices not only extends the life of PVC ball valves but also protects the overall integrity of the piping system.

Related Posts

-

What Makes the Best PVC Ball Valve Ideal for Your Business Needs

-

Why Choosing PVC Ball Valves Can Enhance Your Fluid Control Solutions

-

Understanding the Benefits and Applications of PVC Ball Valves in Modern Plumbing Systems

-

Understanding the Advantages of Electric Actuated Ball Valves in Modern Industrial Applications

-

Exploring the Impact of Motorized Valve Technology on Energy Efficiency in Industrial Applications

-

What Defines an Actuated Ball Valve and Its Importance in Industrial Applications